Our Products

-

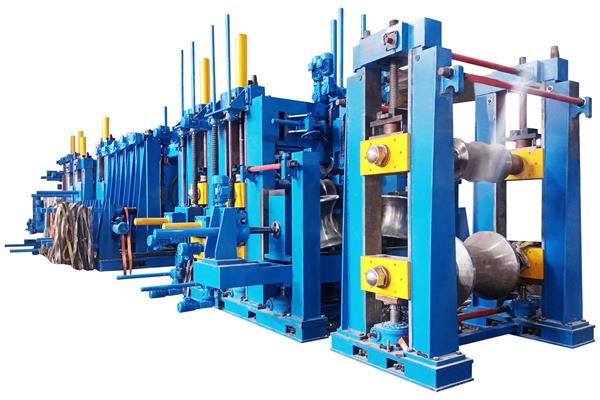

Tube Mill Square to Square ZFII-C

View Details -

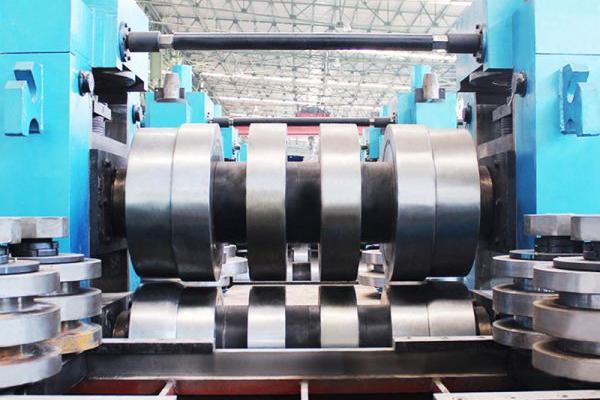

Tube Mill Round to Square Share Rollers

View Details -

Tube Mill Direct Square To Square ZFII-B

View Details -

Tube Mill Round Share Rollers

View Details -

Tube Mill Oil & Gas Transport (API) Pipe Production Line

Tube Mill Round to Square Share Rollers: This innovative forming technology for tube mills enables the production of both round and square tubes using a shared set of rollers. The primary advantage lies in roller commonality, significantly reducing tooling costs and changeover time compared to traditional methods requiring dedicated roller sets for each shape. This leads to increased production flexibility and efficiency.

View Details -

Tube Mill Round & Square Pipe Production Line (Ordinary)

View Details -

Cold Rolled Broad Steel Production Line

View Details -

tube mill rollers

Our selection of Tube Mill Rollers & General Auxiliary Equipment includes forming rollers, sizing rollers, welding stations, cutting systems, and more. Designed for precision and durability, these components ensure consistent and high-quality tube production.

View Details -

Slitting Machine

Our metal slitting machine is engineered for the precise decoiling, slitting, and rewinding of metal plates into multiple, narrower coils of desired width. This crucial process transforms wide steel strips into specific widths, ready to meet the diverse requirements of welded pipe manufacturing, cold-rolled section steel production, and other downstream applications.

View Details

about US

ZTZG Company has been established for 25 years.We are China’s high-end pipe mill equipment manufactor, engineering excellence for your production success.

We are committed to innovating the tube production line for Roller- Sharing.

We leverage advanced technology and meticulous craftsmanship to ensure optimal performance, consistent quality, and intelligent solutions that drive efficiency and profitability for your business.

-

Address

Room 1304 Kaiyuan Building, No.322 East Zhongshan Road, Shijiazhuang, China

-

E-mail

-

Phone

-

Whatsapp

-

Wechat

Our business