100% Original Straight Seam Round Square Rectangular Pipe High Frequency Welding Machine ERW Tube Mill/Pipe Mill

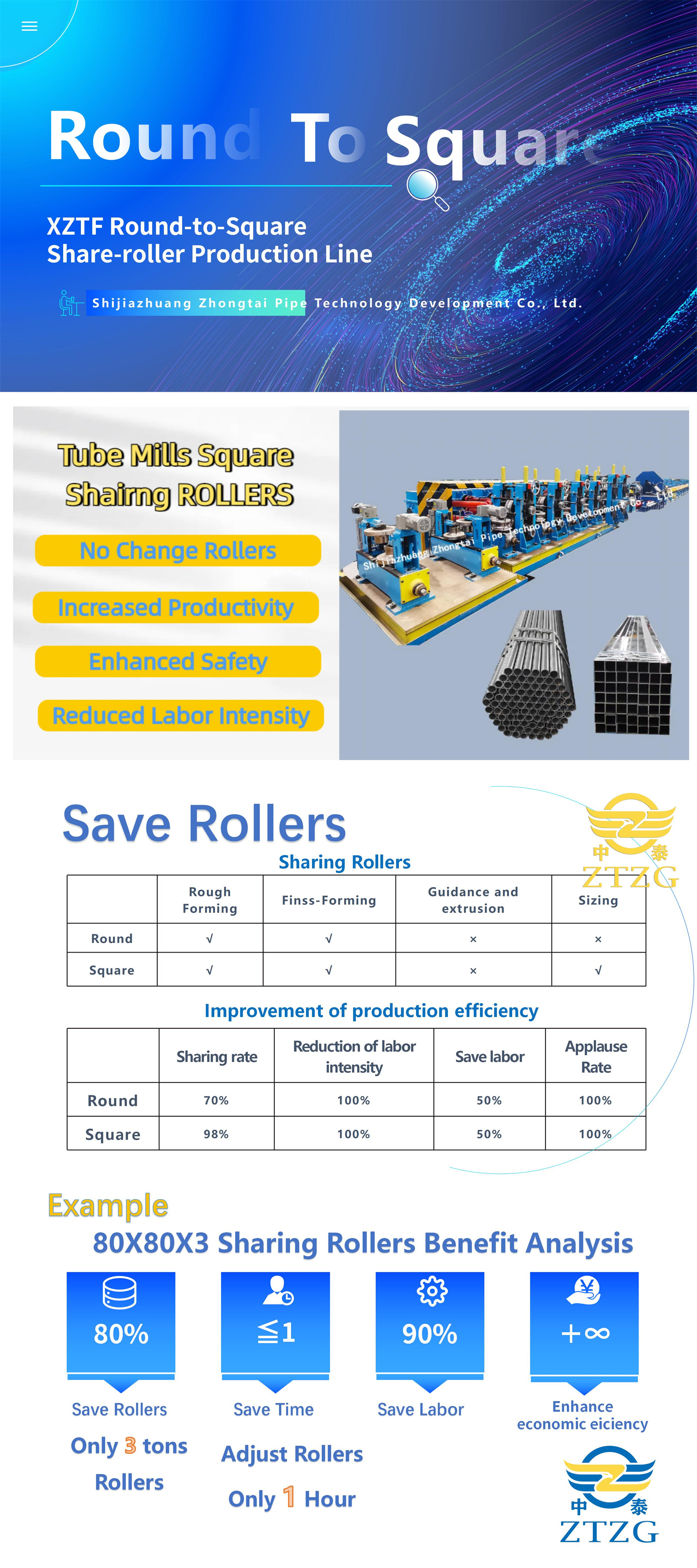

Round Pipe Production on ZTZG Tube Mills: Our round pipe production utilizes shared rollers for the forming section, minimizing tooling changes on our tube mill line. Adjustment is made easy with electrical or automated controls. For the sizing section, rollers are quickly replaced using a side-pull trolley system.

Square Pipe Production on ZTZG Tube Mills: Similar to round pipe production, our square pipe forming section benefits from shared rollers. These shared rollers can be easily adjusted using either electrical or automated controls.

Description

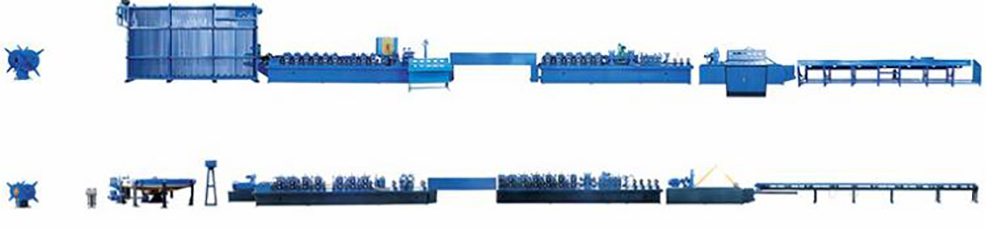

ERW (Electric Resistance Weld) Tube Mill is also called High-Frequency Longitudinal Welded Pipe Production Line. Suitable materials are hot-rolled or cold-rolled strip coils such as plain carbon steel and high-strength steel, etc.

The strip steel is unrolled by the uncoiler, and then enters the accumulator storage after passing through the shear butt welding machine. The strip steel is extruded by rollers and divided into two parts: break-down section and fine pass section. After high-frequency induction welding and sizing part, output the required length of pipe, cut off by flying saw, and finally stack and pack the steel pipe. This production line is a comprehensive complete production line for continuous welding of steel strips into pipes, mainly composed of uncoiler, shear & end welder, accumulator, forming&sizing machine, H.F welder, flying saw, stacking & packing machine.

If there are special purposes or requirements for steel pipes, it is necessary to add testing equipment, such as hydraulic testing machine, intermediate frequency annealing machine, ultrasonic flaw detection machine, etc.

Steel pipe manufacturing process:

Scrolling Up→ Uncoiling → Shear and Welding→ Accumulator→ Forming→ HF induction Welding→ External Burr Removing→ Cooling → Sizing→ Flying Saw → Run Out Table →Inspecting→ Packing→ Warehouse

Features:

1.Suitable for processing GI, carbon steel and black steel tubes, etc.

2.Round and rectangular pipes can be produced with this equipment

3.Production speed can reach up to 120m/min

4.Diameter error tolerance is within 0.5/100 of the pipe's OD

Product information

Advantage

More than 20 years of independent research and development and manufacturing experience. Passed ISO9001 quality system certification and participated in the preparation of a number of industry standards.

ZTZG support customization according to international standards in each region, and provide regular technical information and technical training support.

There is strict quality control in raw materials, processing accuracy, heat treatment, assembly accuracy, standard parts, etc. The pass rate of equipment delivery is 100%.

|

ERW TUBE MILL LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working spead m/min |

|

|

ERW20 |

Ф8-Ф20 |

6x6-15×15 |

0.3-1.5 |

120 |

Read More |

|

ERW32 |

Ф10-Ф32 |

10×10-25×25 |

0.5-2.0 |

120 |

|

|

ERW50 |

Ф20-Ф50 |

15×15-40×40 |

0.8-3.0 |

120 |

|

|

ERW76 |

Ф32-Ф76 |

25×25-60×60 |

1.2-4.0 |

120 |

|

|

ERW89 |

Ф42-Ф89 |

35×35-70×70 |

1.5-4.5 |

110 |

|

|

ERW114 |

Ф48-Ф114 |

40×40-90×90 |

1.5-4.5 |

65 |

|

|

ERW140 |

Ф60-Ф140 |

50×50-110×110 |

2.0-5.0 |

60 |

|

|

ERW165 |

Ф76-Ф165 |

60×60-130×130 |

2.0-6.0 |

50 |

|

|

ERW219 |

Ф89-Ф219 |

70×70-170×170 |

2.0-8.0 |

50 |

|

|

ERW273 |

Ф114-Ф273 |

90×90-210×210 |

3.0-10.0 |

45 |

|

|

ERW325 |

Ф140-Ф325 |

110×110-250×250 |

4.0-12.7 |

40 |

|

|

ERW377 |

Ф165-Ф377 |

130×130-280×280 |

4.0-14.0 |

35 |

|

|

ERW406 |

Ф219-Ф406 |

170×170-330×330 |

6.0-16.0 |

30 |

|

|

ERW508 |

Ф273-Ф508 |

210×210-400×400 |

6.0-18.0 |

25 |

Read More |

|

ERW660 |

Ф325-Ф660 |

250×250-500×500 |

6.0-20.0 |

20 |

Read More |

|

ERW720 |

Ф355-Ф720 |

300×300-600×600 |

6.0-22.0 |

20 |

Read More |

|

STAINLESS STEEL PIPE PRODUCTION LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working speed m/min |

|

|

SS25 |

Ф6-Ф25 |

5×5-20×20 |

0.2-0.8 |

10 |

Read More |

|

SS32 |

Ф6-Ф32 |

5×5-25×25 |

0.2-1.0 |

10 |

Read More |

|

SS51 |

Ф9-Ф51 |

7×7-40×40 |

0.2-1.5 |

10 |

Read More |

|

SS64 |

Ф12-Ф64 |

10×10-50×50 |

0.3-2.0 |

10 |

Read More |

|

SS76 |

Ф25-Ф76 |

20×20-60×60 |

0.3-2.0 |

10 |

Read More |

|

SS114 |

Ф38-Ф114 |

30×30-90×90 |

0.4-2.5 |

10 |

Read More |

|

SS168 |

Ф76-Ф168 |

60×60-130×130 |

1.0-3.5 |

10 |

Read More |

|

SS219 |

Ф114-Ф219 |

90×90-170×170 |

1.0-4.0 |

10 |

Read More |

|

SS325 |

Ф219-Ф325 |

170×170-250×250 |

2.0-8.0 |

3 |

Read More |

|

SS426 |

Ф219-Ф426 |

170×170-330×330 |

3.0-10.0 |

3 |

Read More |

|

SS508 |

Ф273-Ф508 |

210×210-400×400 |

4.0-12.0 |

3 |

Read More |

|

SS862 |

Ф508-Ф862 |

400×400-600×600 |

6.0-16.0 |

2 |

Read More |