ERW76 H.F. Straight Welded Pipe Production Line

Description

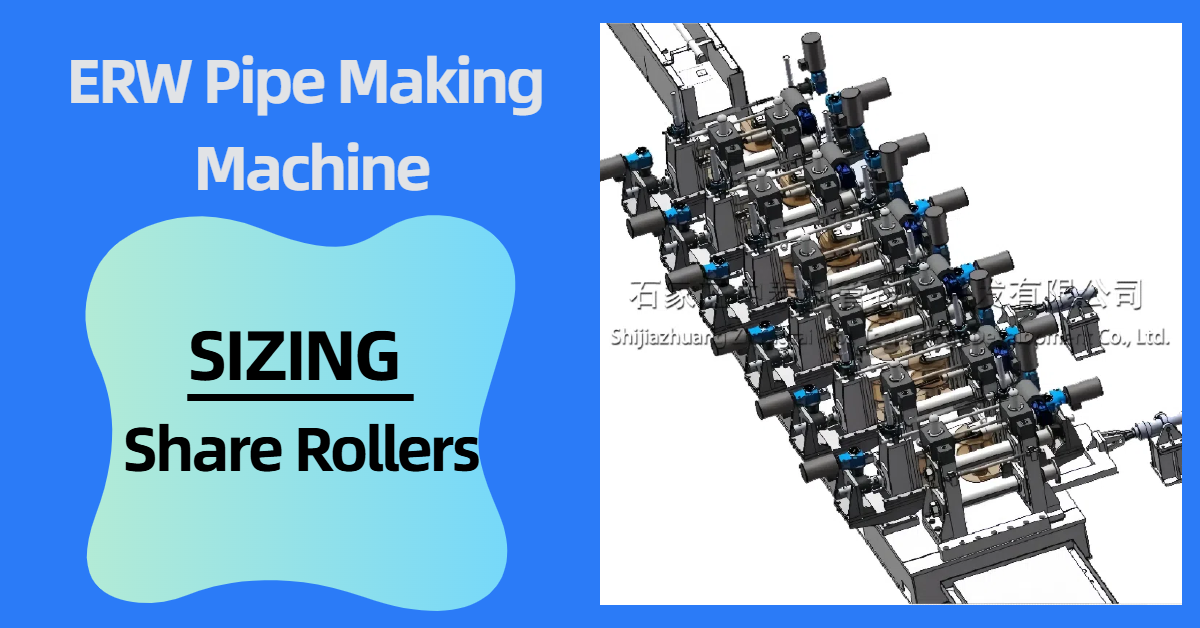

Our high-frequency welded pipe production line offers unmatched versatility in the continuous production of straight seam welded pipes. The system, powered by efficient high-frequency induction welding, enables the production of round pipes as well as square, rectangular, and custom-shaped pipes. A notable advantage is our innovative “common sizing roll” feature: this design allows the same set of sizing rolls to be utilized for multiple pipe profiles, dramatically reducing changeover time and production costs. This advanced technology significantly streamlines the production process. This versatile high-frequency pipe welding machine is perfect for producing diverse pipe types, such as iron pipes, construction pipes, structural pipes, water pipes, oil pipes, and API pipes. Choose our equipment for a reliable and cost-effective pipe production solution.

Technical flow

Scrolling up→ Uncoiling → Shear and Welding→ Spiral accumulator→ Forming → H.F. induction welding→ External burr removing→ Cooling → Sizing→ Flying saw → Run out table →Inspecting→ Packing→ Warehouse

Forming process

| Round pipe | Cold roll forming process | Good roller design |

| Square & rectangular pipe | General round-to-square process | Stable forming process |

| Round-to-square with Turks head | Good pipe quality |

Basic Technical Information of Welded Pipe Production Line

| Produt&yield | Round Pipe | 32mm-76mm Thickness:1.2mm-4.0mm |

| Square & rectangle tube | 25mm×25mm -60mm×60mm Thickness:1.2mm-3.0mm | |

| Length | 6m-12m Length Tolerance: ±3mm | |

| Production Speed | 20-120 m/min | |

| Production capacity | 20,000ton/year | |

| Consumption | Mill installed capacity | 120 kw |

| Line Area | 70m(length) ×5m (width) | |

| worker | 6-8 workers | |

| Raw Material | Material | Q235B(ASTM GR·D,σs 230) |

| Width | 105mm-240mm Thickness: 1.2mm-4.0mm | |

| Coil ID | 450-520mm | |

| Coil OD | Max 1600mm | |

| Coil Weight | 2.0t |

Advantage

1. High production efficiency, line speed can be up to 120m/min.

2. High yielding, the machine works stably at a high speed, which improves the yielding of products.

3. Low wastage, low unit wastage and low production cost.

4. High accuracy, diameter error is only 0.5/100 of the pipe OD.

Products: GI, carbon steel and stainless steel tubes for metallurgy, construction, transportation, machinery and vehicle industries.

Product Detail

|

ERW TUBE MILL LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working spead m/min |

|

|

ERW20 |

Ф8-Ф20 |

6x6-15×15 |

0.3-1.5 |

120 |

Read More |

|

ERW32 |

Ф10-Ф32 |

10×10-25×25 |

0.5-2.0 |

120 |

|

|

ERW50 |

Ф20-Ф50 |

15×15-40×40 |

0.8-3.0 |

120 |

|

|

ERW76 |

Ф32-Ф76 |

25×25-60×60 |

1.2-4.0 |

120 |

|

|

ERW89 |

Ф42-Ф89 |

35×35-70×70 |

1.5-4.5 |

110 |

|

|

ERW114 |

Ф48-Ф114 |

40×40-90×90 |

1.5-4.5 |

65 |

|

|

ERW140 |

Ф60-Ф140 |

50×50-110×110 |

2.0-5.0 |

60 |

|

|

ERW165 |

Ф76-Ф165 |

60×60-130×130 |

2.0-6.0 |

50 |

|

|

ERW219 |

Ф89-Ф219 |

70×70-170×170 |

2.0-8.0 |

50 |

|

|

ERW273 |

Ф114-Ф273 |

90×90-210×210 |

3.0-10.0 |

45 |

|

|

ERW325 |

Ф140-Ф325 |

110×110-250×250 |

4.0-12.7 |

40 |

|

|

ERW377 |

Ф165-Ф377 |

130×130-280×280 |

4.0-14.0 |

35 |

|

|

ERW406 |

Ф219-Ф406 |

170×170-330×330 |

6.0-16.0 |

30 |

|

|

ERW508 |

Ф273-Ф508 |

210×210-400×400 |

6.0-18.0 |

25 |

Read More |

|

ERW660 |

Ф325-Ф660 |

250×250-500×500 |

6.0-20.0 |

20 |

Read More |

|

ERW720 |

Ф355-Ф720 |

300×300-600×600 |

6.0-22.0 |

20 |

Read More |

|

STAINLESS STEEL PIPE PRODUCTION LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working speed m/min |

|

|

SS25 |

Ф6-Ф25 |

5×5-20×20 |

0.2-0.8 |

10 |

Read More |

|

SS32 |

Ф6-Ф32 |

5×5-25×25 |

0.2-1.0 |

10 |

Read More |

|

SS51 |

Ф9-Ф51 |

7×7-40×40 |

0.2-1.5 |

10 |

Read More |

|

SS64 |

Ф12-Ф64 |

10×10-50×50 |

0.3-2.0 |

10 |

Read More |

|

SS76 |

Ф25-Ф76 |

20×20-60×60 |

0.3-2.0 |

10 |

Read More |

|

SS114 |

Ф38-Ф114 |

30×30-90×90 |

0.4-2.5 |

10 |

Read More |

|

SS168 |

Ф76-Ф168 |

60×60-130×130 |

1.0-3.5 |

10 |

Read More |

|

SS219 |

Ф114-Ф219 |

90×90-170×170 |

1.0-4.0 |

10 |

Read More |

|

SS325 |

Ф219-Ф325 |

170×170-250×250 |

2.0-8.0 |

3 |

Read More |

|

SS426 |

Ф219-Ф426 |

170×170-330×330 |

3.0-10.0 |

3 |

Read More |

|

SS508 |

Ф273-Ф508 |

210×210-400×400 |

4.0-12.0 |

3 |

Read More |

|

SS862 |

Ф508-Ф862 |

400×400-600×600 |

6.0-16.0 |

2 |

Read More |