Factory Customized Stainless Steel Tube Mill Line Double Phase Steel Pipe Mill Machine Duct Welding Machine Pipe Producing Line Industry Machinery

It is actually a good way to boost our products and solutions and repair. Our mission should be to produce imaginative products and solutions to clients using a fantastic working experience for Factory Customized Stainless Steel Tube Mill Line Double Phase Steel Pipe Mill Machine Duct Welding Machine Pipe Producing Line Industry Machinery, We're prepared to present you with the most effective ideas over the designs of the orders in a qualified way for those who need. While in the meantime, we continue to keep on producing new technologies and building new designs so as to help make you ahead from the line of this small business.

It is actually a good way to boost our products and solutions and repair. Our mission should be to produce imaginative products and solutions to clients using a fantastic working experience for China Pipe Making Machine and Steel Pipe Making Machine, Our advantages are our innovation, flexibility and reliability which have been built during last 20 years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products and solutions in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market.

Specialized in Pipe Production Line

More than 23 years...

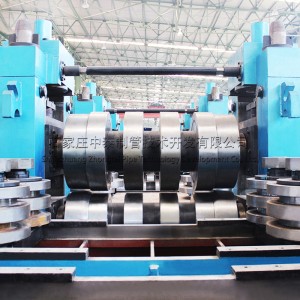

Stainless Steel Pipe Production Line is designed to produce welded stainless steel pipes of 6mm to 862mm in OD and with a maximum wall thickness of 16mm, as well as corresponding square and rectangular pipe.

Stainless Steel Pipe Production Line

ZTZG series stainless steel welded pipe production lines are mainly for the production of stainless steel and carbon steel thicker pipes (round pipes) mainly used in industrial areas or high requirements in the decorative areas. The products produced by this series of units are round pipe, square pipe, rectangular pipe, also can produce oval pipe, half round pipe, plum pipe and other special-shaped pipe.

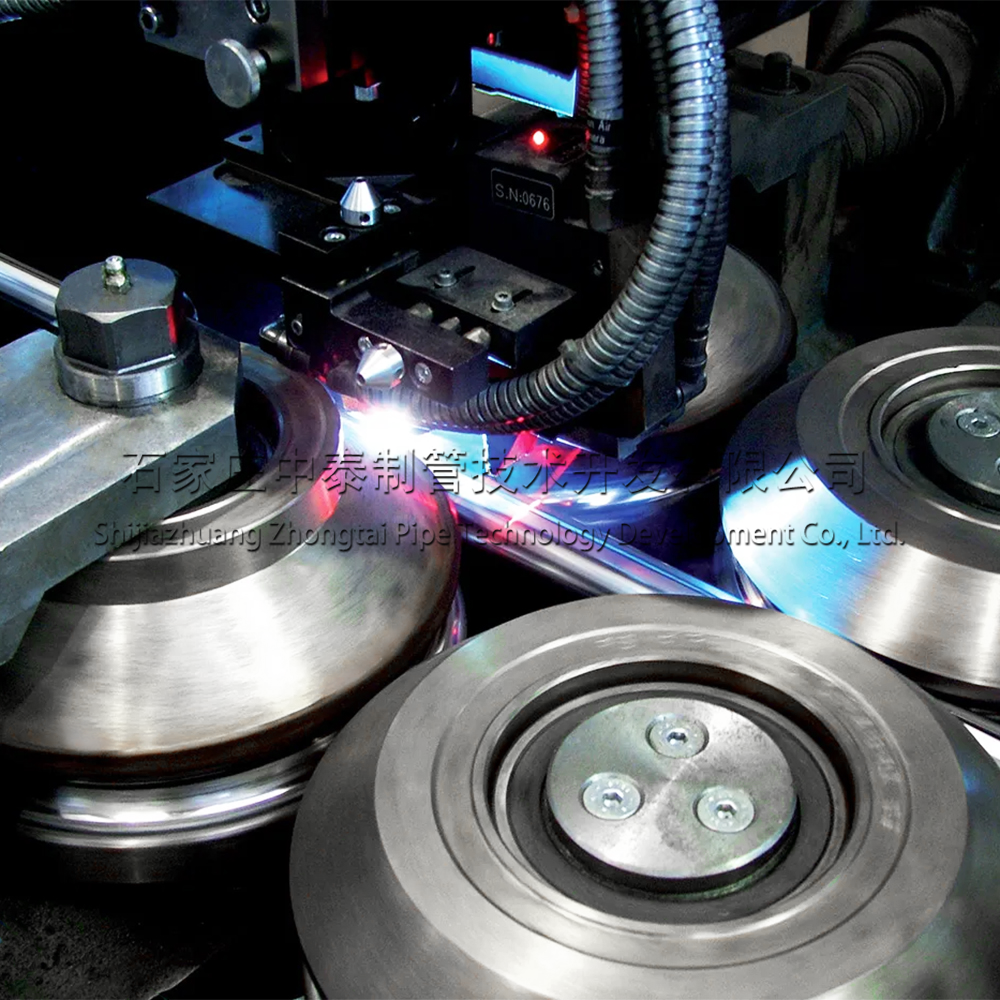

Stainless Steel pipe manufacturing process

Scrolling Up→ Uncoiling → Scrolling up→ Forming → Welding→ Grinding → Sizing→ Straightening→ Cutting → Run out table →Inspecting→ Packing→ Warehouse

Product Information

Line Component

Material Information

Finished Product

Line Specification

Line Component

| Line Component | Uncoiler Forming & Sizing Machine Welder Cutting Saw Stacking & Packing Machine |

| Special | Hydraulic testing machine, intermediate frequency annealing machine, ultrasonic flaw detection machine, etc. |

Material Information

|

Material |

TP304, TP316, TP310, S31254, Duplex, Super-Duplex & all other Stainless Steel Grades |

| Strip Steel Width | 320mm-2400mm |

| Strip Steel Thickness | 1.2 - 4.0mm |

|

Strip Steel Coil |

Inner diameter:Φ 610mm-760mm Outer diameter:Φ 1300mm-2300mm Weight: Max=4.0 T |

Finished Product

| Round Pipe | Φ6-Φ862 mm |

| Thickness | 0.2-16.0 mm |

| Square & Rectangular Tube | 5×5-600x600 mm |

| Thickness | 0.2-16.0 mm |

| Length | 6-14 m |

Line Specification

| Forming Speed | 2-10 m/min (Attn: Max pipe diameter thickness doesn't correspond with the max speed) |

| Feeding Direction | Left feeding (or right feeding), option by customer |

| Electric Installed Capacity | 400-2500 kW |

| Production Line Size | 78m(length)×6m(width)-400m(length)×40m (width) |

| Color of Machines | Blue or customized |

| Yearly Out-put | About 40,000 tons |

The Largest Stainless Steel SS820 Pipe Production Line

"In addition, we have developed a new process for stainless steel pipes with large pipe diameter and wall thickness. This stainless steel production line can realize the mold sharing of the entire production line. When the specification of the production pipe changes, it is unnecessary to replace the mold and rely on the servo motor to adjust, realizing intelligent production. In 2020, ZTZG signed the largest stainless steel SS820 pipe production line in China."

High Automation

One key adjustment of servo motor.

Low Wastage

Low unit wastage and low production cost.

High Accuracy

Diameter error is only 0.5/100 of the pipe OD.

Product Application

We can design and manufacture pipe making machine according to customers’ requirements.

Everything you need to create a steel pipe production line

Our Certificate

Our Company

Shijiazhuang Zhongtai Pipe Technology Development Co., Ltd.was established in 2000 locating in Shijiazhuang, the capital city of Hebei Province. The factory covers an area of 67,000 square meters. Our main products consist high frequency straight welded pipe production line, cold roll steel production line, multi-function cold roll steel/welded pipe production line, slitting line production line, stainless steel pipe mill, various pipe mill auxiliary equipment and rollers, etc.

Ready for a new

Business Adventure?

Contact Now!

It is actually a good way to boost our products and solutions and repair. Our mission should be to produce imaginative products and solutions to clients using a fantastic working experience for Factory Customized Stainless Steel Tube Mill Line Double Phase Steel Pipe Mill Machine Duct Welding Machine Pipe Producing Line Industry Machinery, We're prepared to present you with the most effective ideas over the designs of the orders in a qualified way for those who need. While in the meantime, we continue to keep on producing new technologies and building new designs so as to help make you ahead from the line of this small business.

Factory Customized China Pipe Making Machine and Steel Pipe Making Machine, Our advantages are our innovation, flexibility and reliability which have been built during last 20 years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products and solutions in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market.

|

ERW TUBE MILL LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working spead m/min |

|

|

ERW20 |

Ф8-Ф20 |

6x6-15×15 |

0.3-1.5 |

120 |

Read More |

|

ERW32 |

Ф10-Ф32 |

10×10-25×25 |

0.5-2.0 |

120 |

|

|

ERW50 |

Ф20-Ф50 |

15×15-40×40 |

0.8-3.0 |

120 |

|

|

ERW76 |

Ф32-Ф76 |

25×25-60×60 |

1.2-4.0 |

120 |

|

|

ERW89 |

Ф42-Ф89 |

35×35-70×70 |

1.5-4.5 |

110 |

|

|

ERW114 |

Ф48-Ф114 |

40×40-90×90 |

1.5-4.5 |

65 |

|

|

ERW140 |

Ф60-Ф140 |

50×50-110×110 |

2.0-5.0 |

60 |

|

|

ERW165 |

Ф76-Ф165 |

60×60-130×130 |

2.0-6.0 |

50 |

|

|

ERW219 |

Ф89-Ф219 |

70×70-170×170 |

2.0-8.0 |

50 |

|

|

ERW273 |

Ф114-Ф273 |

90×90-210×210 |

3.0-10.0 |

45 |

|

|

ERW325 |

Ф140-Ф325 |

110×110-250×250 |

4.0-12.7 |

40 |

|

|

ERW377 |

Ф165-Ф377 |

130×130-280×280 |

4.0-14.0 |

35 |

|

|

ERW406 |

Ф219-Ф406 |

170×170-330×330 |

6.0-16.0 |

30 |

|

|

ERW508 |

Ф273-Ф508 |

210×210-400×400 |

6.0-18.0 |

25 |

Read More |

|

ERW660 |

Ф325-Ф660 |

250×250-500×500 |

6.0-20.0 |

20 |

Read More |

|

ERW720 |

Ф355-Ф720 |

300×300-600×600 |

6.0-22.0 |

20 |

Read More |

|

STAINLESS STEEL PIPE PRODUCTION LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working speed m/min |

|

|

SS25 |

Ф6-Ф25 |

5×5-20×20 |

0.2-0.8 |

10 |

Read More |

|

SS32 |

Ф6-Ф32 |

5×5-25×25 |

0.2-1.0 |

10 |

Read More |

|

SS51 |

Ф9-Ф51 |

7×7-40×40 |

0.2-1.5 |

10 |

Read More |

|

SS64 |

Ф12-Ф64 |

10×10-50×50 |

0.3-2.0 |

10 |

Read More |

|

SS76 |

Ф25-Ф76 |

20×20-60×60 |

0.3-2.0 |

10 |

Read More |

|

SS114 |

Ф38-Ф114 |

30×30-90×90 |

0.4-2.5 |

10 |

Read More |

|

SS168 |

Ф76-Ф168 |

60×60-130×130 |

1.0-3.5 |

10 |

Read More |

|

SS219 |

Ф114-Ф219 |

90×90-170×170 |

1.0-4.0 |

10 |

Read More |

|

SS325 |

Ф219-Ф325 |

170×170-250×250 |

2.0-8.0 |

3 |

Read More |

|

SS426 |

Ф219-Ф426 |

170×170-330×330 |

3.0-10.0 |

3 |

Read More |

|

SS508 |

Ф273-Ф508 |

210×210-400×400 |

4.0-12.0 |

3 |

Read More |

|

SS862 |

Ф508-Ф862 |

400×400-600×600 |

6.0-16.0 |

2 |

Read More |