Factory Supply Hf Straight Seam Pipe Mill, Pipe Making Machine, Tube Mill

Driven by our motto of "Technology Innovation Leads to Excellence," we have become one of the most technologically innovative, cost-efficient, and price-competitive manufacturers of tube mills and tube making machines in China. We understand the paramount importance of product quality and service, adhering to the business philosophy of "People-Oriented, Genuine to the World, Your Satisfaction is Our Pursuit." We not only customize product designs for tube mills and tube making machines based on customer samples and specific requirements to meet diverse market demands, but also provide personalized solutions for different clients. We warmly welcome friends from home and abroad to visit, discuss cooperation, seek common development, and achieve mutual success!

Description

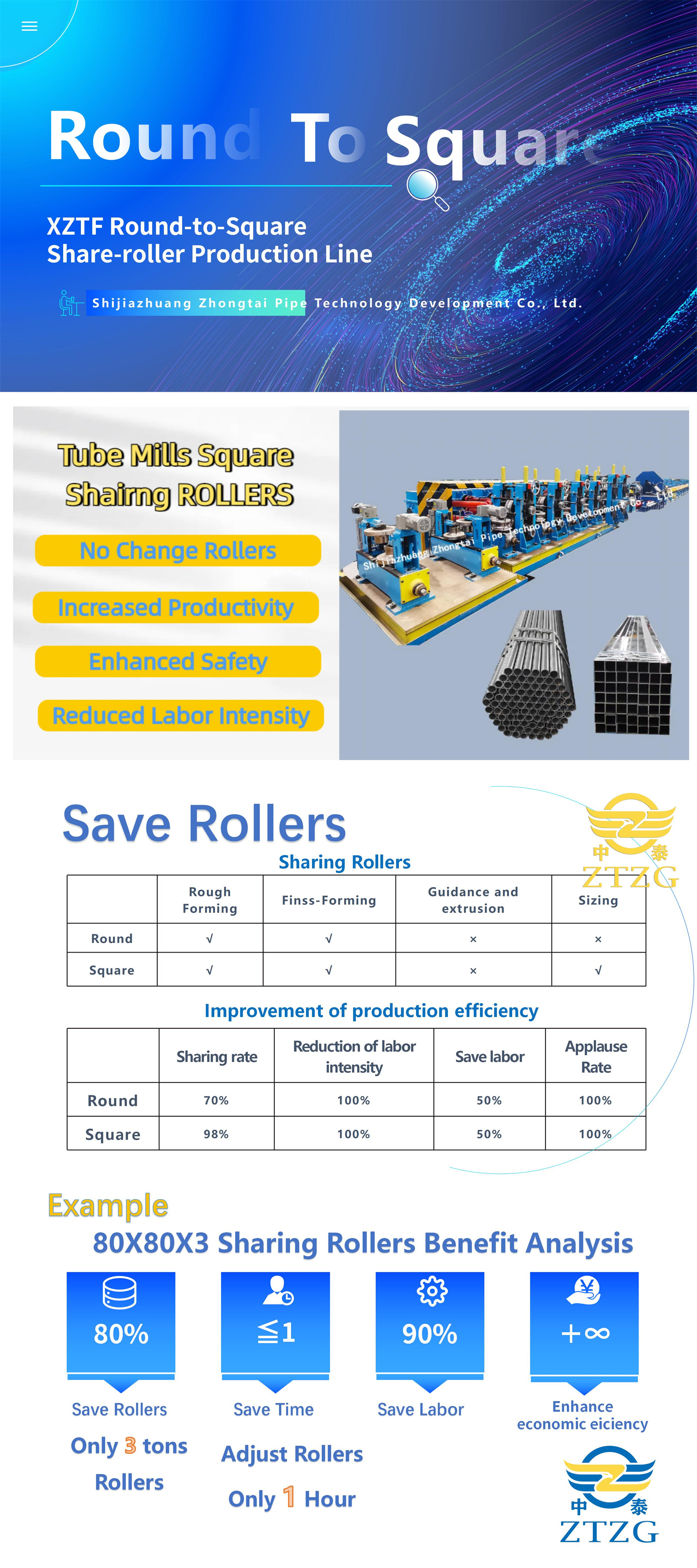

We specialize in the design and manufacture of tube mills and tube making machines, focusing on delivering cost-effective and customizable solutions. A distinguishing feature of our tube mill is its “common roll” design: this means that the roll set used for square and rectangular tube production can be used for the entire process without requiring a change of the rolls. Similarly, the formation of round tubes is achieved without the need to swap or change the forming rolls, further simplifying the production process and saving you both time and resources. As a leading provider of tube making machines, we understand the importance of efficient and reliable solutions. We warmly invite you to contact us to discuss your specific requirements.

The complete HF welded pipe mill is made up of an entry section, mill section, cut-off section and finishing section, the steel pipe manufacturing process including:

Scrolling Up→ Uncoiling → Shear and Welding→ Spiral Accumulator→ Forming→ HF induction Welding→ External Burr Removing→ Cooling → Sizing→ Flying Saw → Run Out Table →Inspecting→ Packing→ Warehouse.

Features

1.Suitable for processing carbon steel

2.Round and rectangular pipes can be produced with this equipment

3.Production speed can reach up to 120m/min

4.Diameter error tolerance is within 0.5/100 of the pipe’s OD

Product information

| Product&Yield | Round Pipe | 38mm-127mm |

| Square & Rectangle Tube | 30x30mm-100x100mm | |

| Length | 6-12m | |

| Production Speed | 50-120m/min | |

| Production Capacity | 5000T | |

| Consumption | Mill installed Capacity | 300KW-750KW |

| Line Area | 40X5M-80X10m | |

| Worker | 6-8 workers | |

| Raw Material | Material | ST-37 Q345 Q235 |

| Width | 120mm-400mm | |

| Coil ID | Φ470~508mm | |

| Coil OD | Φ1000~1800mm | |

| Coil Weight | 2-5Ton |

Our Advantage

1) More than 20 years of independent research and development and manufacturing experience. Passed ISO9001 quality system certification and participated in the preparation of a number of industry standards.

2)ZTZG support customization according to international standards in each region, and provide regular technical information and technical training support.

3) There is strict quality control in raw materials, processing accuracy, heat treatment, assembly accuracy, standard parts, etc. The pass rate of equipment delivery is 100%.

Factory Supply China Pipe Machine and Pipe-Making Machine, the company attaches great importance to product quality and service, based on the business philosophy "good with people, genuine to whole world, your satisfaction is our pursuit". we design products, according to customer's requirements, to meet the needs of the market and offer different customers with personalized service. Our company warmly welcomes friends at home and abroad to visit, to discuss cooperation and seek common development!

|

ERW TUBE MILL LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working spead m/min |

|

|

ERW20 |

Ф8-Ф20 |

6x6-15×15 |

0.3-1.5 |

120 |

Read More |

|

ERW32 |

Ф10-Ф32 |

10×10-25×25 |

0.5-2.0 |

120 |

|

|

ERW50 |

Ф20-Ф50 |

15×15-40×40 |

0.8-3.0 |

120 |

|

|

ERW76 |

Ф32-Ф76 |

25×25-60×60 |

1.2-4.0 |

120 |

|

|

ERW89 |

Ф42-Ф89 |

35×35-70×70 |

1.5-4.5 |

110 |

|

|

ERW114 |

Ф48-Ф114 |

40×40-90×90 |

1.5-4.5 |

65 |

|

|

ERW140 |

Ф60-Ф140 |

50×50-110×110 |

2.0-5.0 |

60 |

|

|

ERW165 |

Ф76-Ф165 |

60×60-130×130 |

2.0-6.0 |

50 |

|

|

ERW219 |

Ф89-Ф219 |

70×70-170×170 |

2.0-8.0 |

50 |

|

|

ERW273 |

Ф114-Ф273 |

90×90-210×210 |

3.0-10.0 |

45 |

|

|

ERW325 |

Ф140-Ф325 |

110×110-250×250 |

4.0-12.7 |

40 |

|

|

ERW377 |

Ф165-Ф377 |

130×130-280×280 |

4.0-14.0 |

35 |

|

|

ERW406 |

Ф219-Ф406 |

170×170-330×330 |

6.0-16.0 |

30 |

|

|

ERW508 |

Ф273-Ф508 |

210×210-400×400 |

6.0-18.0 |

25 |

Read More |

|

ERW660 |

Ф325-Ф660 |

250×250-500×500 |

6.0-20.0 |

20 |

Read More |

|

ERW720 |

Ф355-Ф720 |

300×300-600×600 |

6.0-22.0 |

20 |

Read More |

|

STAINLESS STEEL PIPE PRODUCTION LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working speed m/min |

|

|

SS25 |

Ф6-Ф25 |

5×5-20×20 |

0.2-0.8 |

10 |

Read More |

|

SS32 |

Ф6-Ф32 |

5×5-25×25 |

0.2-1.0 |

10 |

Read More |

|

SS51 |

Ф9-Ф51 |

7×7-40×40 |

0.2-1.5 |

10 |

Read More |

|

SS64 |

Ф12-Ф64 |

10×10-50×50 |

0.3-2.0 |

10 |

Read More |

|

SS76 |

Ф25-Ф76 |

20×20-60×60 |

0.3-2.0 |

10 |

Read More |

|

SS114 |

Ф38-Ф114 |

30×30-90×90 |

0.4-2.5 |

10 |

Read More |

|

SS168 |

Ф76-Ф168 |

60×60-130×130 |

1.0-3.5 |

10 |

Read More |

|

SS219 |

Ф114-Ф219 |

90×90-170×170 |

1.0-4.0 |

10 |

Read More |

|

SS325 |

Ф219-Ф325 |

170×170-250×250 |

2.0-8.0 |

3 |

Read More |

|

SS426 |

Ф219-Ф426 |

170×170-330×330 |

3.0-10.0 |

3 |

Read More |

|

SS508 |

Ф273-Ф508 |

210×210-400×400 |

4.0-12.0 |

3 |

Read More |

|

SS862 |

Ф508-Ф862 |

400×400-600×600 |

6.0-16.0 |

2 |

Read More |