Hot New Products ERW Pipe Making Machines Pipe Mill Welded Pipes Machinery Pipe and Tube Mill

Since our inception, our enterprise has consistently regarded product quality as the lifeblood of our business. We are committed to continuously enhancing our manufacturing technology and making improvements to product excellence. To ensure the highest standards, we continuously strengthen our total quality administration in strict accordance with the national standard ISO 9001:2000 for China High Frequency Welding and Iron Machinery ERW. Our advanced tube mill production lines are a crucial part of our dedication to superior quality. This commitment to quality is reflected in the outstanding reputation our merchandise has earned in the international market, known for their good quality, competitive prices, and prompt shipment. Utilizing state-of-the-art techniques and meticulously managed production processes on our tube mill lines, we consistently deliver products that meet and exceed customer expectations. We are sincerely looking forward to cooperating with more overseas customers based on mutual benefits, and providing them with high-quality products manufactured on our dependable tube mill equipment. Our commitment to excellence extends to every facet of our operations, from design and manufacturing to after-sales service, ensuring that our tube mill technology delivers reliable and high-performance solutions.

Description

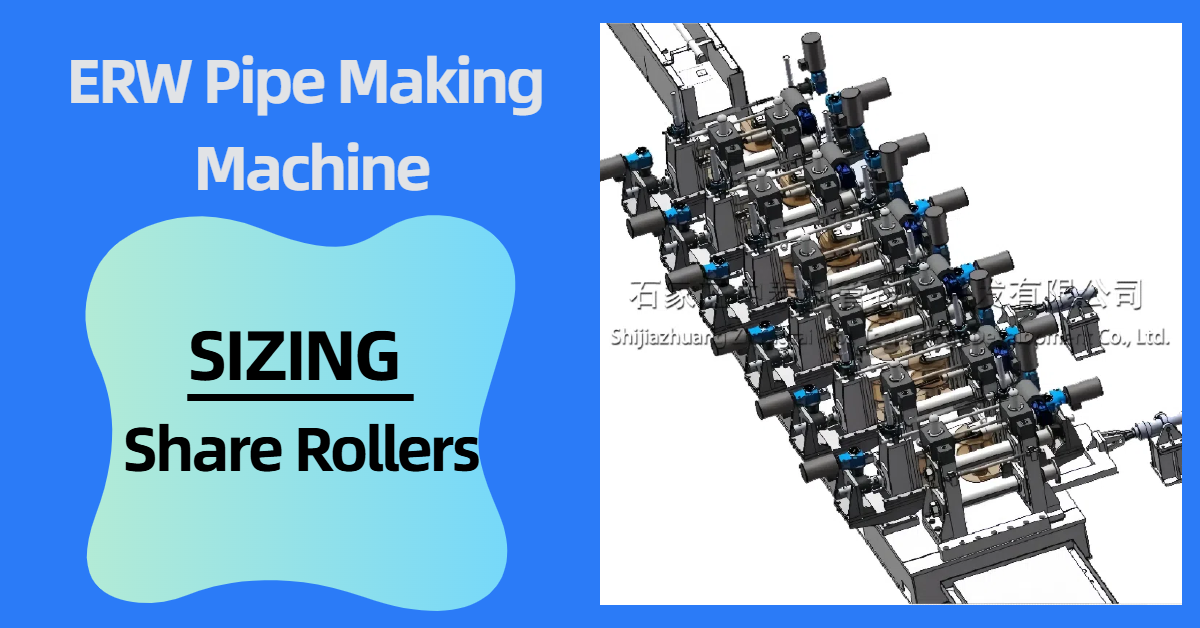

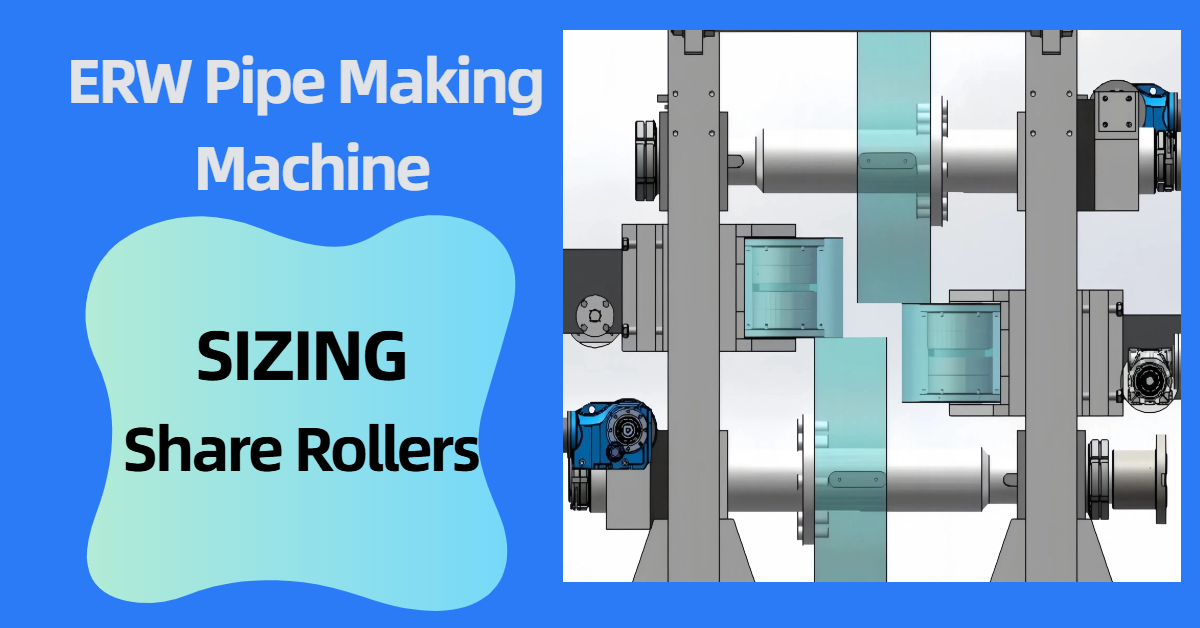

The forming section adopts the principle of rolling forming, gradually forming the strip into a billet tube, and then heating the welding seam through the Kelvin effect and the proximity effect of high-frequency current to make it reach the welding temperature and complete the welding. The scraping device will then cut off the extra burrs created during the welding stage, and the heating tube will go through a water-cooling process to reduce the tube temperature to a standard temperature. Next, another round of roller sizing will further shape the size and thickness of the pipe to the desired diameter or size. Finally, the tube will go through the Turks head for square tube production.

Technical process:

Scrolling Up→ Uncoiler→ Shear & End Welding→ Accumulator→ Forming part→ HF Welder → External Burr Removing→ Water Cooling → Sizing→ Flying Saw → Run Out Table →Inspecting→ Packing→ Warehouse.

Another name for the rough straightened device is Turks head, it is the final step of sizing section. It is used to shape the round pipe into square or rectangular tube through precisely positioned rollers, and then rough-straighten it. It consists of four four-roller straightening machines, with its head able to revolve and move horizontally. The first 3 turks head are used for round-square shaping and the 4th one is for rough straightening.

Product information

| Produt&Yield | Round Pipe | 48mm-127mm |

| Square & Rectangle Tube | 40x40mm-100x100mm | |

| Length | 6-12m | |

| Production Speed | 50-120m/min | |

| Production Capacity | 15000 Ton | |

| Consumption | Mill Installed Capacity | 300KW-750KW |

| Line Area | 40X5M-80X10m | |

| Worker | 6-8 workers | |

| Raw Material | Material | ST-37 ST-52 Q235 Q345 |

| Width | 160mm-400mm | |

| Coil ID | Φ470~508mm | |

| Coil OD | Φ1000~1800mm | |

| Coil Weight | 2-5Ton |

Our Advantage

After absorbing advanced pipe making technology from both abroad and domestic, our innovative designed production line and each single unit of the production line are not only economical but also practical. Passed ISO9001 quality system certification and participated in the preparation of a number of industry standards. ZTZG support customization according to international standards in each region, and provide regular technical information and technical training support.

Hot New Products China High-Frequency Welding and Iron Machinery ERW, our merchandise has enjoyed a great reputation for their good quality, competitive prices, and prompt shipment in the international market. Presently, we are sincerely looking forward to cooperating with more overseas customers based on mutual benefits.

|

ERW TUBE MILL LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working spead m/min |

|

|

ERW20 |

Ф8-Ф20 |

6x6-15×15 |

0.3-1.5 |

120 |

Read More |

|

ERW32 |

Ф10-Ф32 |

10×10-25×25 |

0.5-2.0 |

120 |

|

|

ERW50 |

Ф20-Ф50 |

15×15-40×40 |

0.8-3.0 |

120 |

|

|

ERW76 |

Ф32-Ф76 |

25×25-60×60 |

1.2-4.0 |

120 |

|

|

ERW89 |

Ф42-Ф89 |

35×35-70×70 |

1.5-4.5 |

110 |

|

|

ERW114 |

Ф48-Ф114 |

40×40-90×90 |

1.5-4.5 |

65 |

|

|

ERW140 |

Ф60-Ф140 |

50×50-110×110 |

2.0-5.0 |

60 |

|

|

ERW165 |

Ф76-Ф165 |

60×60-130×130 |

2.0-6.0 |

50 |

|

|

ERW219 |

Ф89-Ф219 |

70×70-170×170 |

2.0-8.0 |

50 |

|

|

ERW273 |

Ф114-Ф273 |

90×90-210×210 |

3.0-10.0 |

45 |

|

|

ERW325 |

Ф140-Ф325 |

110×110-250×250 |

4.0-12.7 |

40 |

|

|

ERW377 |

Ф165-Ф377 |

130×130-280×280 |

4.0-14.0 |

35 |

|

|

ERW406 |

Ф219-Ф406 |

170×170-330×330 |

6.0-16.0 |

30 |

|

|

ERW508 |

Ф273-Ф508 |

210×210-400×400 |

6.0-18.0 |

25 |

Read More |

|

ERW660 |

Ф325-Ф660 |

250×250-500×500 |

6.0-20.0 |

20 |

Read More |

|

ERW720 |

Ф355-Ф720 |

300×300-600×600 |

6.0-22.0 |

20 |

Read More |

|

STAINLESS STEEL PIPE PRODUCTION LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working speed m/min |

|

|

SS25 |

Ф6-Ф25 |

5×5-20×20 |

0.2-0.8 |

10 |

Read More |

|

SS32 |

Ф6-Ф32 |

5×5-25×25 |

0.2-1.0 |

10 |

Read More |

|

SS51 |

Ф9-Ф51 |

7×7-40×40 |

0.2-1.5 |

10 |

Read More |

|

SS64 |

Ф12-Ф64 |

10×10-50×50 |

0.3-2.0 |

10 |

Read More |

|

SS76 |

Ф25-Ф76 |

20×20-60×60 |

0.3-2.0 |

10 |

Read More |

|

SS114 |

Ф38-Ф114 |

30×30-90×90 |

0.4-2.5 |

10 |

Read More |

|

SS168 |

Ф76-Ф168 |

60×60-130×130 |

1.0-3.5 |

10 |

Read More |

|

SS219 |

Ф114-Ф219 |

90×90-170×170 |

1.0-4.0 |

10 |

Read More |

|

SS325 |

Ф219-Ф325 |

170×170-250×250 |

2.0-8.0 |

3 |

Read More |

|

SS426 |

Ф219-Ф426 |

170×170-330×330 |

3.0-10.0 |

3 |

Read More |

|

SS508 |

Ф273-Ф508 |

210×210-400×400 |

4.0-12.0 |

3 |

Read More |

|

SS862 |

Ф508-Ф862 |

400×400-600×600 |

6.0-16.0 |

2 |

Read More |