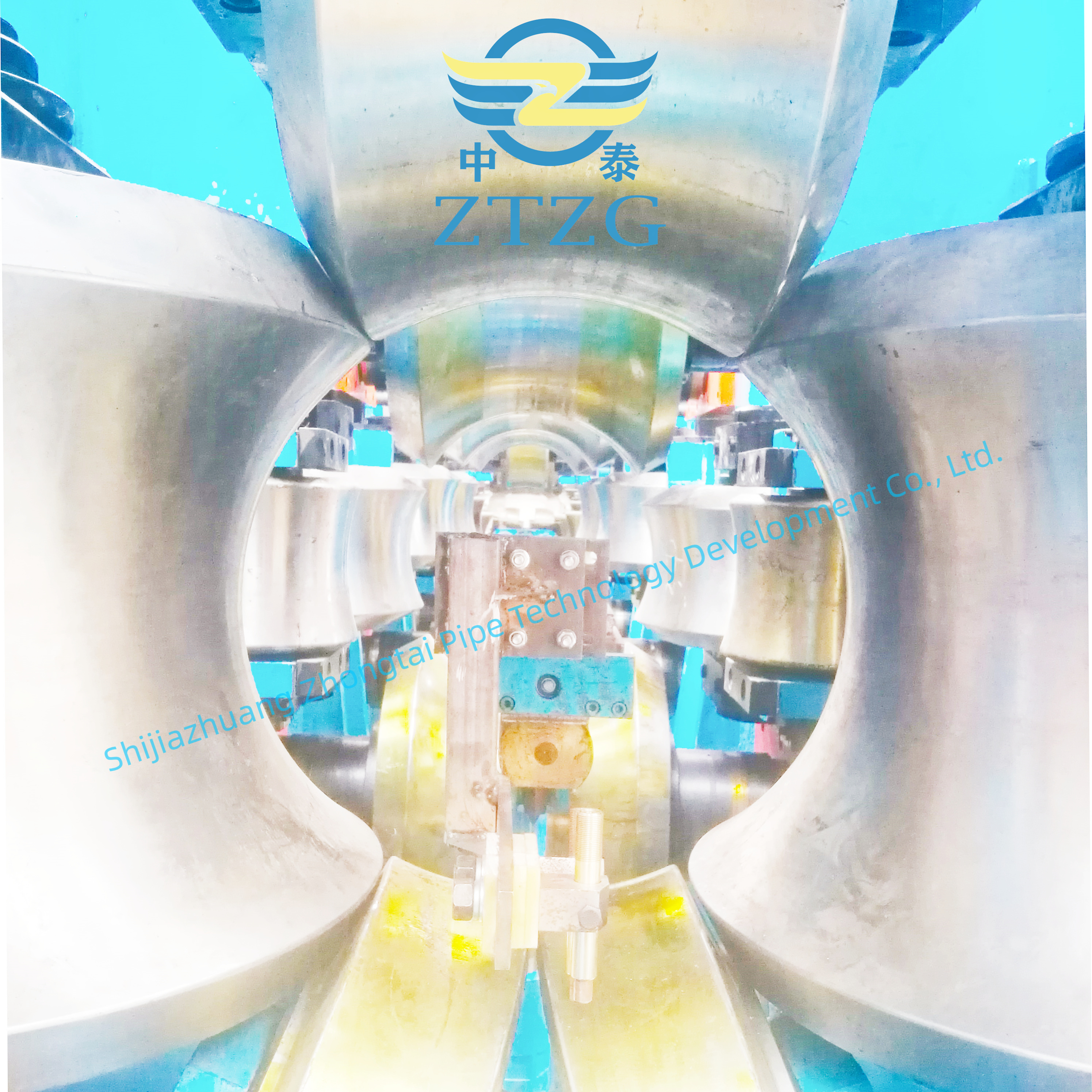

508 API ERW pipe mill :

The API508 production line is used to produce oil and gas pipelines with an outer diameter of 273mm-508mm and a wall thickness of 6.0mm-18.0mm.

Technological process:

Coiling → uncoiler → straightening machine → pinch leveling → automatic shear butt welding machine → horizontal spiral loop → ultrasonic flaw detection of strip steel → forming (ZTF) → high-frequency induction welding → removal of external burrs → removal of internal burrs → grinding → online detection → weld annealing furnace → air cooling → water cooling → sizing → cutting → roller table → straightening → flat chamfering → hydrostatic test → offline ultrasonic flaw detection → punch → inspection → weighing and length measurement → coating and printing → packaging → warehousing

API508 production line advantages:

The ZTF forming process can save up to 80% or more of the rollers;

2. Automatic adjustment, saving time for roll changing;

3. The deformation of each support is uniform, improving the quality of the pipe;

4. High strength, stable and high-speed operation of the machine;

5. Excellent products and high yield.

6. Siemens, Yaskawa, and domestic motors are available.

Post time: Jul-05-2024