Advancement and main features of FFX molding technology

(1) The FFX forming machine can produce welded pipes with higher steel grade, thinner and thicker walls. Since the deformation of FFX erw pipe making machine forming technology is mainly based on horizontal rolls, and the vertical rolls in the post-rough forming stage do not need to use inner rolls to control deformation, the equipment structure has the characteristics of both softness and rigidity, and it is easy to achieve high strength and high rigidity and can stabilize Produce high-quality welded pipes above 219 mm, D/t=10 ~ 100, and steel grade up to P110.

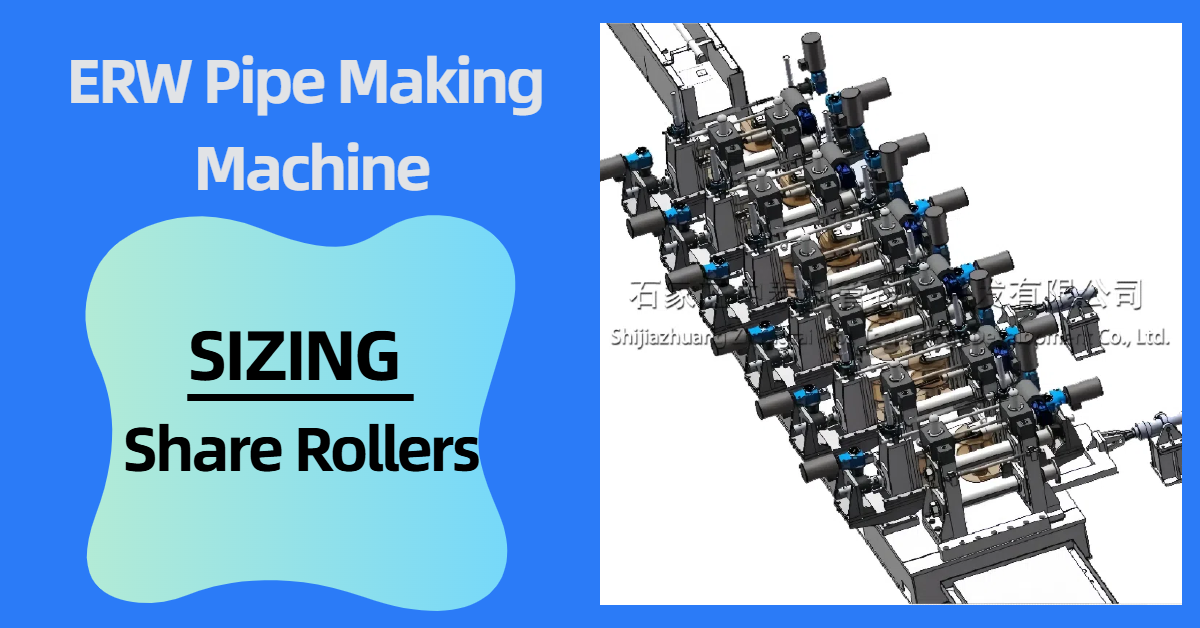

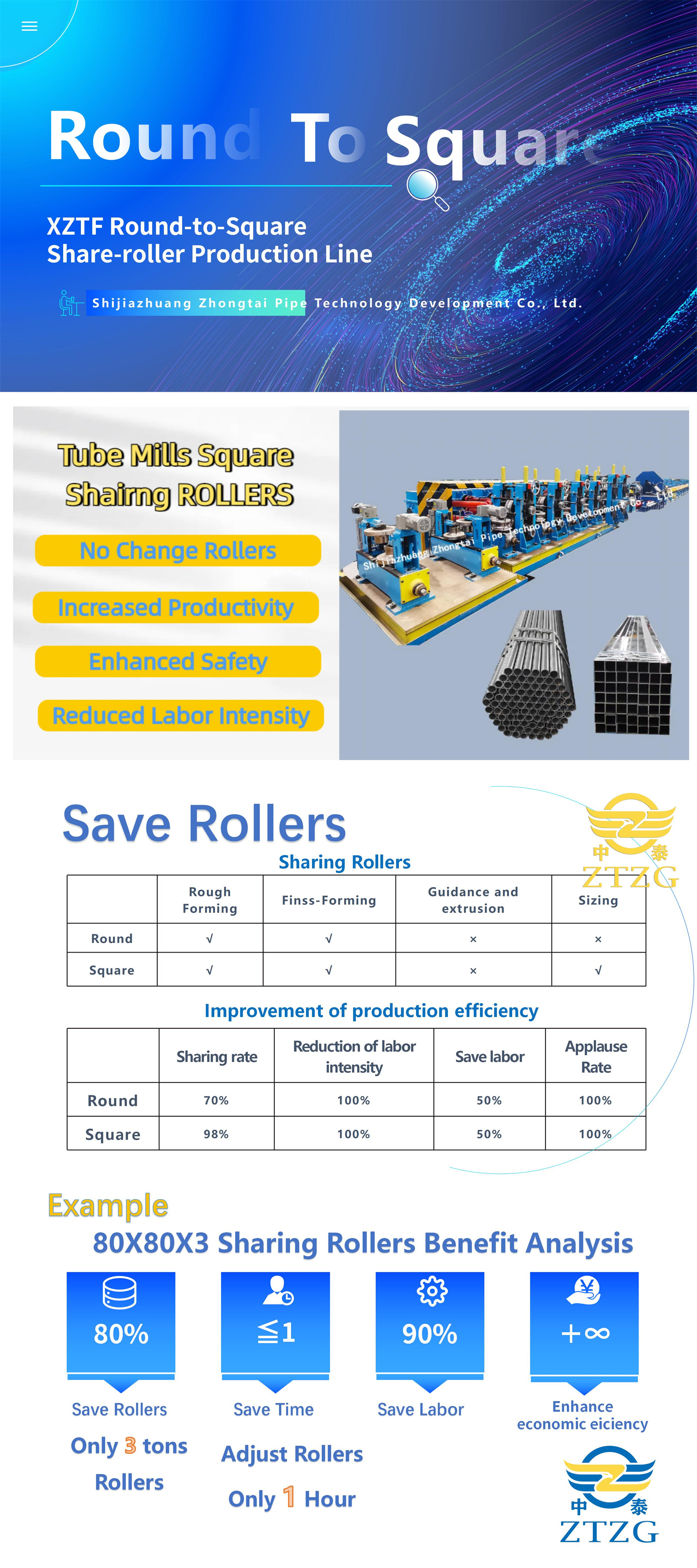

(2) Horizontal rolls and vertical rolls of the FFX forming section in a tube making machine are fully shared. In FFX forming technology, the involute roll shape and roll-to-roll bending method are organically combined, so that horizontal rolls and vertical rolls can be completely shared. For example, the third-generation ZTF roll pipe forming section in a tube mill, developed by ZTZG, only needs to share a set of rolls for rough forming. This reduces the cost of the rollers and simplifies the use and management of the rolls.

(3) The distribution of deformation is reasonable, and the molding process is stable. In the rough forming stage of a tube mill, the large deformation method mainly adopts horizontal rollers, so that the curvature of the side of the open tube is close to that of the finished welded pipe, and the deformation of the fine forming is small. This reasonable distribution of deformation makes the forming stable and overcomes the disadvantages of row roll forming. The hidden danger of welded pipe defects is caused by the unreasonable distribution of deformation in older tube mills.

(4) The continuous bending forming method, utilized in a tube mill, is adopted to create the best conditions for high-frequency welding. FFX forming technology, as implemented in a tube making machine, adopts the continuous bending forming method and makes full use of the respective forming characteristics of horizontal rolls and vertical rolls. This ensures that there is no dead zone of deformation in the strip section, and more importantly, it effectively overcomes the deformation caused by changes in strip thickness and strength. The minimization of elastic recovery improves molding accuracy and stability within the tube mill. After rough forming in the tube mill, the edge of the strip steel is completely plastically deformed, and the curvature of the edge of the open tube is very close to that of the finished tube. The deformation during fine forming is minimal, ensuring the shape of the open tube after rough forming is preserved, which creates optimal conditions for high-frequency welding within the tube mill.

(5) Improves the quality of the welded pipe produced by a tube mill. Compared with traditional roll forming technology, the FFX forming technology, implemented in a tube making machine, also improves the quality of the welded pipe in the following two aspects: First, after rough forming within the tube mill, since the curvature of the edge of the open tube is very close to the finished pipe body, misalignment from the extrusion rollers during the finishing stage is minimized, even for high-strength and thick-walled welded pipes. After fine forming within the tube mill, the two sides of the strip edge are essentially parallel (not a positive V-shape or inverted V-shape) butt joints. Uniform burrs are formed on the inner and outer surfaces of the welded pipe, which is conducive to burr scraping. At the same time, a larger V-shaped welding angle can be used in front of the high-frequency welding machine, effectively preventing welding defects such as gray spots. Secondly, due to the continuous flange forming method employed in the tube mill and the unique roll pass design, any part of the strip steel section only undergoes a maximum of one deformation during the rough forming stage. The deformation transition is well-connected, preventing any single area from being repeatedly deformed, and thus, minimizing local thinning due to roll pressure. Therefore, the deformation is uniform, the internal stress is low, and the overall internal quality of the welded pipe produced by the tube mill is improved.

To sum up, our ZTF-IV ERW pipe forming technology, implemented within a tube mill, combines many advantages of traditional roll forming and flower roll forming methods, demonstrating a significant advancement. ZTZG has produced multiple ZTF welded pipe production lines for various enterprises. Among them, Tangshan Wenfeng Qiyuan Steel designed and produced the fourth-generation FFX automatic forming production line within their tube mill, which incorporates computer control, signifying that ZTZG’s innovative concepts have entered a new stage. Our ZTF(FFX) Flexible Forming technology, utilized in tube making machines, will continue to improve and evolve through ongoing use within the tube mill environment.

Post time: Feb-04-2023