In today’s fast-paced manufacturing environment, enhancing operational efficiency is critical for staying competitive. Our new ERW pipe mill is specifically designed to help clients significantly improve productivity and streamline their production processes.

One of the standout features of our new ERW pipe mill is its advanced automation capabilities. By minimizing manual intervention, we reduce the potential for human error, leading to consistent product quality and substantial time savings. The intuitive user interface allows operators to quickly adjust settings, facilitating seamless transitions between different pipe sizes and specifications without lengthy setup times.

Energy efficiency is another key benefit of our innovative design. The mill utilizes cutting-edge technologies that lower operational costs while supporting sustainable manufacturing practices. By optimizing power consumption, you not only reduce expenses but also contribute to a greener production process, making your operations more environmentally friendly.

Real-time monitoring systems integrated into the new ERW pipe mill provide instant feedback on machine performance. This feature enables proactive maintenance, significantly minimizing downtime and ensuring that your production schedules are consistently met. With predictive analytics, potential issues can be identified before they escalate, enhancing overall reliability.

The increased speed and precision of the new mill empower you to meet growing market demands without compromising on quality. This combination of efficiency, reliability, and high-quality output positions your business to outperform competitors and capture greater market share.

Investing in our new ERW pipe mill will transform your production capabilities, equipping your business to thrive in an ever-evolving industry landscape. Experience the difference that enhanced efficiency can make for your operations today.

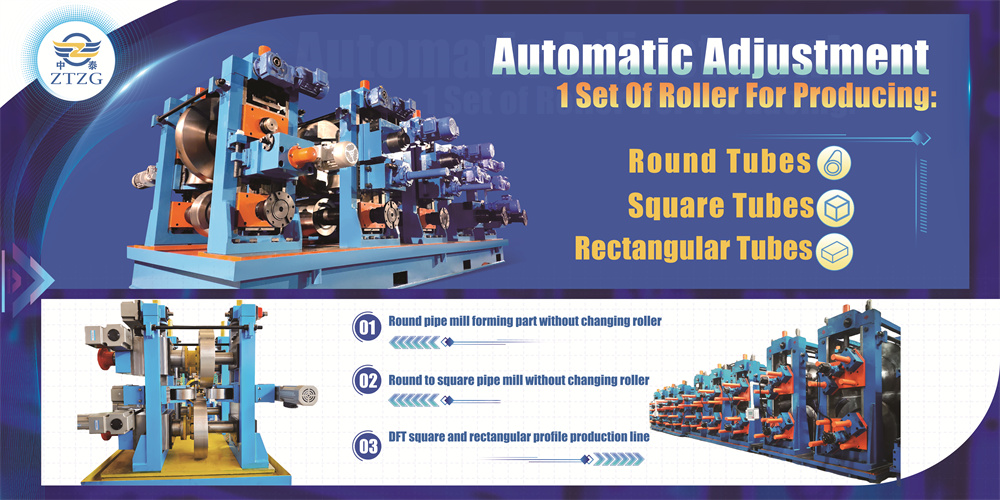

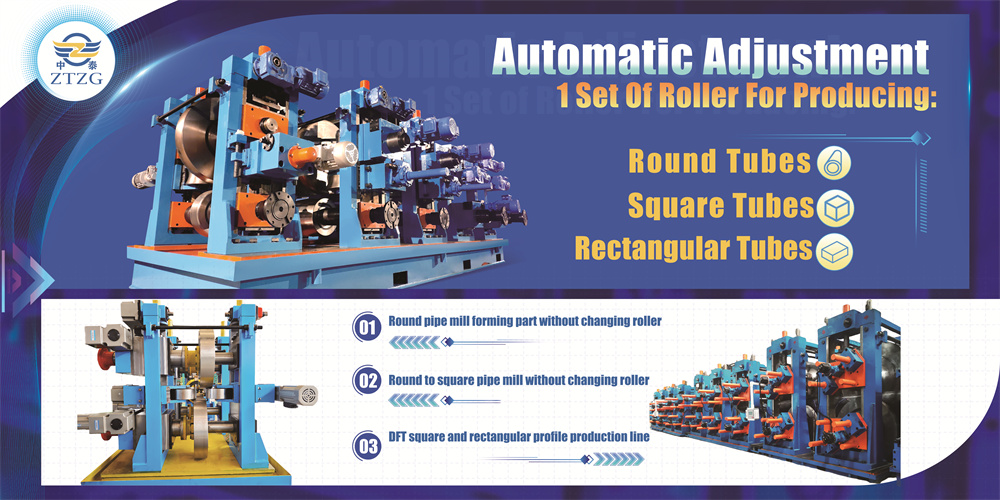

The new ERW PIPE MILL launched by ZTZG can help customers improve production efficiency in the following aspects:

1. Reduce roll changing time and increase production: When producing rectangular tubes, the round-to-square process is used, and the entire machine does not need to change molds;

2. High efficiency and low labor intensity: The motor adjusts the opening and closing, lifting and lowering of the rollers, and workers no longer have to climb high and low. With a gentle touch, they can quickly change the rollers;

3. High-quality products: producing defect-free steel pipes: R-angle thickening, symmetrical four corners, strengthened;

4. Cost savings: The molds do not need to be replaced: only one set of rollers is needed for production, and all square and rectangular tube specifications can be produced within a certain range. Greatly save mold investment and reduce equipment wear;

Post time: Oct-31-2024