Tube mills/ERW pipe mill/ERW tube making machine

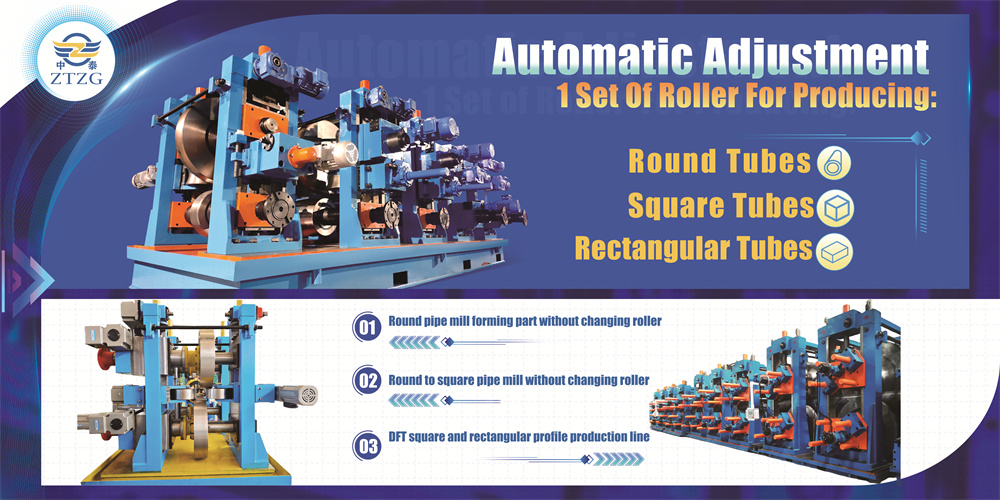

In the manufacturing realm, innovation is the key to staying competitive and efficient.ZTZG Company has recently introduced a remarkable new non-mold-change process that is set to transform the landscape of production.

One of the most significant advantages of this novel process is enhanced production flexibility. Traditional manufacturing often requires time-consuming mold changes when switching between different product designs or variants. However, with ZTZG’s new process, the need for such mold alterations is minimized or even eliminated. This means that manufacturers can respond more swiftly to market demands and customer requests. They can easily transition from producing one product to another without the long downtimes associated with mold replacement. This flexibility not only accelerates the time-to-market for new products but also allows for more customized and on-demand production, catering to the diverse and ever-changing needs of consumers.

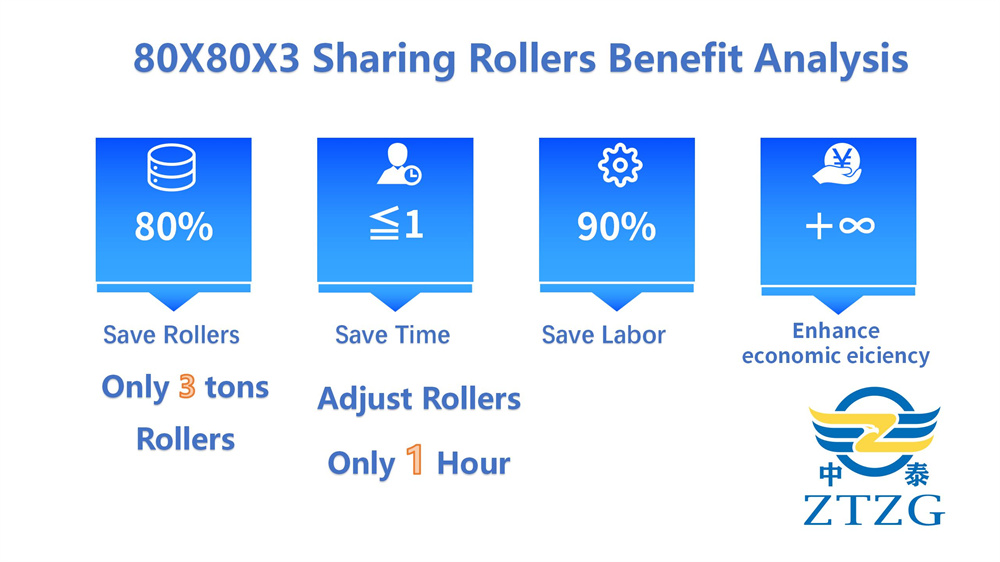

Cost reduction is another major plus. The elimination of frequent mold changes leads to a substantial decrease in associated costs. There are no longer expenses related to purchasing new molds, storing and maintaining a large inventory of molds, or the labor costs of performing mold changeovers. This cost-effective approach makes production more economical, especially for small to medium-sized production runs where the cost of molds can be a significant burden. It also enables companies to allocate their financial resources more strategically, perhaps investing in other areas such as research and development or marketing.

Moreover, the new process of ZTZG Company contributes to improved product quality. Since there is less disruption and variability caused by mold changes, the consistency and precision of the manufactured products are enhanced. Each unit is more likely to meet the exacting standards and specifications, reducing the likelihood of defects and rejects. This results in higher customer satisfaction and fewer returns or quality issues, which can have a positive impact on a company’s reputation and bottom line.

In addition, the non-mold-change process offers increased productivity. With shorter setup times and continuous production flow, more products can be manufactured in a given time period. This boost in productivity can help companies meet tight production deadlines, increase their output capacity, and gain a competitive edge in the market. It also allows for better utilization of production facilities and equipment, maximizing the return on investment.

In conclusion, ZTZG Company’s new non-mold-change process is a game-changer. Its advantages in terms of flexibility, cost reduction, quality improvement, and productivity enhancement make it a highly attractive option for manufacturers across various industries. As the manufacturing world continues to evolve, such innovative processes will undoubtedly play a crucial role in shaping the future of production.

Post time: Dec-03-2024