In the erw pipe mill industry, improving production efficiency, reducing costs, and simplifying operations have always been key concerns for manufacturers. Recently, our company introduced the “Sharing Rollers pipe making machine”, designed specifically to address these challenges. This innovative equipment not only significantly saves on rollers costs but also enhances operational convenience, offering a tailored solution for our customers.

Saving Rollers, Reducing Production Costs:

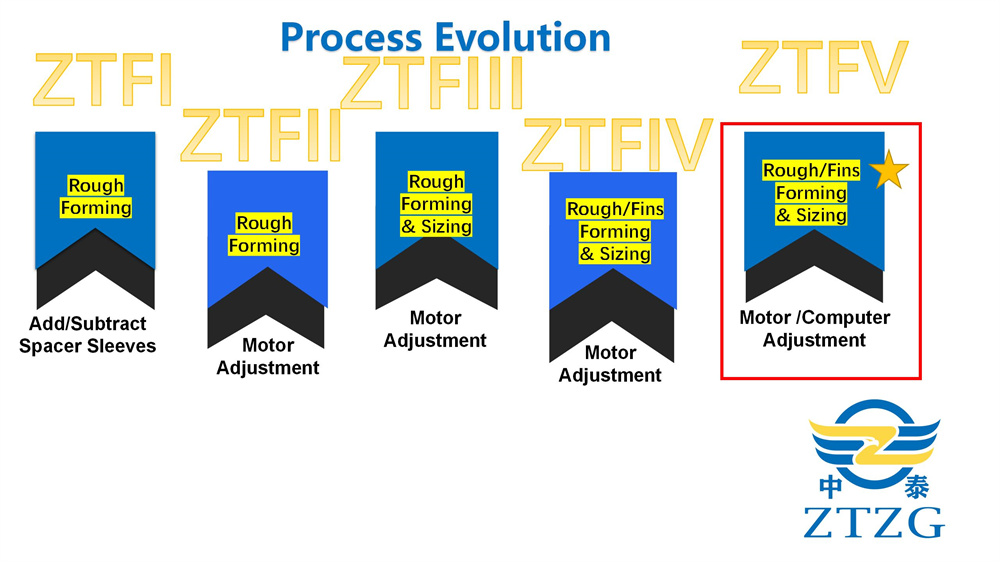

In traditional,ERW pipe mills, rollers are essential components that directly affect the pipe forming process. However, the need for a large number of rollers at every production stage increases equipment procurement costs and maintenance frequency. To solve this problem, our Sharing Rollers Equipment features a unique shared design concept, allowing multiple production stages to use the same set of rollers, substantially reducing the number of rollers needed.

This innovative design not only cuts down on the number of rollers required in the production process but also extends their lifespan, reducing maintenance frequency. Customers no longer need to purchase separate rollers for each production stage, simplifying cost management and logistics.

Convenient Operation Design, Improving Production Efficiency:

In equipment design, we always prioritize operational convenience. The introduction of Sharing Rollers Equipment enables operators to perform multiple production processes without having to change rollers, significantly boosting production efficiency. Additionally, the automated control system makes adjustments easier, allowing operators to set up the machine with minimal manual input.

For modern pipe making machines, fast switching and efficient production flow are crucial for improving market competitiveness. Our Sharing Rollers tube mill, based on these needs, ensures smooth operation at every production stage through intelligent control, eliminating delays due to roller changes.

Enhancing Flexibility and Cost-Effectiveness of the Production Line:

The design of Sharing Rollers Equipment not only simplifies operation but also increases the flexibility of the production line. Whether producing ERW pipes or other types of pipe materials, customers can easily switch between production modes with simple adjustments, meeting the demands of various pipe specifications. The equipment’s adaptability means manufacturers can continuously improve utilization and output, no matter what the production requirements are.

Conclusion:

As a company dedicated to the development of high-end welding pipe equipment, we are always committed to providing our customers with the most valuable technological innovations. The introduction of Sharing Rollers Equipment marks another breakthrough in enhancing production efficiency and cost control. With this equipment, customers can not only significantly reduce production costs but also improve automation, further strengthening their market competitiveness.

To learn more about ERW pipe mills and pipe making machines, please visit our official website or contact our customer service team. We are ready to provide the best solutions for you.

Post time: Nov-06-2024