The manufacturing landscape is constantly evolving, and one of the most significant advancements in recent years has been the automation of tube mills. But what exactly makes tube mill automation so essential?

Let’s start with the basics. A tube mill is a complex piece of equipment that transforms raw materials into finished tubes. In the past, this process was largely manual, requiring a significant amount of labor and time. However, with the advent of automation, tube mills have become more efficient and productive.

One of the main advantages of tube mill automation is its ability to improve quality control. Automated systems can precisely monitor and adjust various parameters during the production process, ensuring that each tube meets the highest standards. This is particularly important in industries where tubes are used in critical applications, such as aerospace and medical devices.

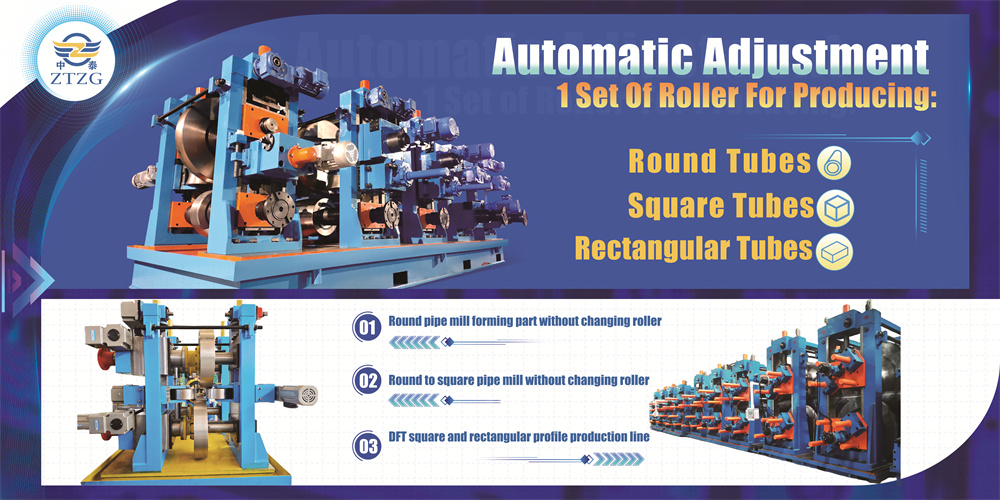

Another benefit is increased flexibility. Automated tube mills can be programmed to produce different types and sizes of tubes with ease. This allows manufacturers to quickly adapt to changing market demands and customer requirements.

Furthermore, automation reduces waste. By optimizing the production process and minimizing errors, less material is wasted, resulting in cost savings and a more sustainable operation.

Think about the future of manufacturing. As technology continues to advance, the demand for high-quality tubes will only grow. Tube mill automation is the key to meeting this demand and staying competitive in the global marketplace.

In addition to the practical benefits, automated tube mills also offer a more pleasant working environment. With less manual labor involved, workers are freed from repetitive and strenuous tasks, allowing them to focus on more creative and strategic activities.

In conclusion, tube mill automation is a game-changer for the manufacturing industry. It unlocks new levels of productivity, quality, and flexibility, while also reducing costs and waste. Embrace the power of automation and see your tube production business soar to new heights.

Post time: Dec-08-2024