1.Introduction

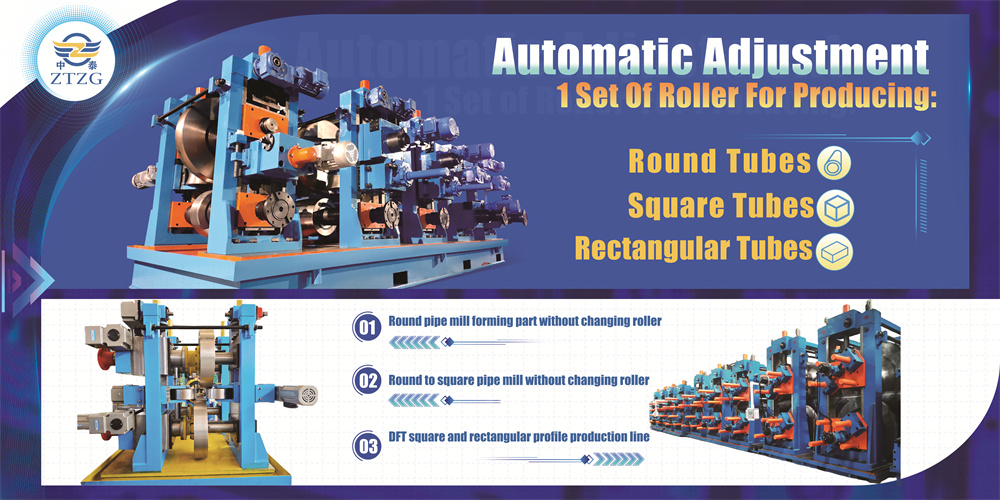

In today’s competitive industrial landscape, innovation is the key to success. ZTZG company has come up with an innovative round-to-square Rollers sharing process that is set to revolutionize production across various industries. This unique approach not only enhances production efficiency but also offers cost-effective solutions.

The round-to-square Rollers sharing process developed by ZTZG is truly innovative. It allows for seamless transition between different shapes, reducing the need for multiple Rollerss and thereby saving costs. This innovative company is constantly striving to find new and better ways to improve production processes.

Just like the erw tube mill that is known for saving rollers, reducing production costs, boasting convenient operation design, improving production efficiency, enhancing flexibility and cost-effectiveness, ZTZG’s round-to-square Rollers sharing process offers similar advantages. It is a game-changer in the world of manufacturing, providing a solution that is both practical and efficient.

The Rollers sharing process is not only innovative but also highly cost-effective. It reduces the overall cost of production by minimizing the need for multiple Rollerss. This makes it an attractive option for businesses looking to cut costs without sacrificing quality.

In conclusion, ZTZG company’s round-to-square Rollers sharing process is a remarkable innovation that holds great promise for the future of manufacturing. With its innovative design and cost-effective nature, it is sure to make a significant impact on various industries.

2.What is Rollers Sharing?

Rollers sharing refers to the practice of using a single Rollers for different production processes or shapes. In the context of ZTZG company, Rollers sharing involves the use of a round-to-square Rollers that can be used for both round and square products. This technology works by allowing the Rollers to be adjusted or transformed to fit the specific shape required for a particular production run.

The benefits of Rollers sharing at ZTZG are numerous. Firstly, it significantly reduces production costs. By using a single Rollers for multiple shapes, the company can save on the expense of purchasing and maintaining multiple Rollerss. This is similar to the benefits of printer sharing, where multiple users can share a single printer to save on hardware costs.

Secondly, Rollers sharing increases flexibility. The ability to use one Rollers for different shapes gives ZTZG the freedom to adapt to changing market demands and customer requirements. It’s like a shape-shifting technology that allows the company to be more responsive and competitive.

In addition, Rollers sharing can lead to improved efficiency. With less time spent on changing Rollerss and setting up new production lines, the company can increase production output and reduce lead times.

Finally, Rollers sharing is a sustainable practice. By reducing the number of Rollerss needed, ZTZG can reduce waste and environmental impact. It’s a win-win for the company and the planet.

Overall, Rollers sharing is a revolutionary technology that is transforming the way ZTZG operates. With its many benefits, it’s no wonder that Rollers sharing is becoming increasingly popular in the manufacturing industry.

3.ZTZG’s Rollers Sharing Process

ZTZG’s round-to-square Rollers sharing process involves several specific steps and techniques. Firstly, advanced technology plays a crucial role in making this process possible. For instance, computer-aided design and manufacturing (CAD/CAM) systems are used to precisely design and modify the Rollerss to fit different shapes.

The process starts with careful analysis of the production requirements. Engineers determine whether a round-to-square transition is needed for a particular batch of products. If so, they use the advanced software to adjust the Rollers parameters. This might involve changing the dimensions, curvature, and other characteristics of the Rollers.

Once the adjustments are made, the Rollers is tested to ensure its functionality and accuracy. Advanced testing techniques, such as simulation software and physical prototypes, are employed to check for any potential issues.

The role of engineering in this process cannot be overstated. Skilled engineers design the Rollerss with precision and durability in mind. They consider factors such as material strength, heat resistance, and wear and tear to ensure that the Rollerss can withstand the rigors of production.

Moreover, continuous research and development are carried out to improve the Rollers sharing process. New materials and manufacturing techniques are explored to enhance the performance and longevity of the Rollerss.

In conclusion, ZTZG’s round-to-square Rollers sharing process is a complex combination of advanced technology and engineering expertise. It represents a significant advancement in the field of manufacturing and offers numerous benefits to businesses looking for efficient and cost-effective production solutions.

4.Benefits for Industries

ZTZG’s round-to-square Rollers sharing process has a significant positive impact on different industries. Firstly, it leads to improved product quality. With advanced technology and precision engineering, the Rollerss can ensure consistent and accurate shaping of products, resulting in higher quality end products. This is similar to how efforts to improve product quality in other industries, such as ensuring strict quality control in the production of electronics or automobiles, can enhance customer satisfaction and brand reputation.

Secondly, the Rollers sharing process shortens production cycles. By reducing the time spent on changing Rollerss and setting up new production lines, industries can increase production output and reduce lead times. For example, just as various manufacturing processes have found ways to shorten production periods, like using advanced manufacturing techniques to reduce production cycle time, ZTZG’s approach does the same. This not only helps companies meet market demands more quickly but also gives them a competitive edge in a fast-paced business environment.

Finally, it enhances competitiveness. Industries that adopt ZTZG’s Rollers sharing process can benefit from cost savings, improved quality, and shorter production cycles. This combination allows them to offer products at competitive prices while maintaining high quality. In a global marketplace where competitiveness is crucial, this can be a game-changer. It’s like how companies constantly strive to find innovative solutions to gain an edge over their competitors, and ZTZG’s Rollers sharing process provides just such an opportunity.

5.Conclusion

In conclusion, ZTZG’s round-to-square Rollers sharing process is a significant innovation in the manufacturing landscape. It combines advanced technology and engineering expertise to offer numerous benefits.

This process not only reduces production costs by minimizing the need for multiple Rollerss, but also increases flexibility, allowing the company to adapt to changing market demands. The use of computer-aided design and manufacturing systems ensures precision and durability, while continuous research and development leads to improved performance and longevity of the Rollerss.

The benefits for industries are clear. It leads to improved product quality, shortens production cycles, and enhances competitiveness. Just as the erw tube mill revolutionizes production with its saving rollers, reducing costs, convenient operation design, improving efficiency, enhancing flexibility, and cost-effectiveness, ZTZG’s Rollers sharing process is a game-changer in the manufacturing world.

With its unique approach of transforming from round to square Rollerss, ZTZG is setting new standards in the industry. It is a sustainable practice that reduces waste and environmental impact. As manufacturing continues to evolve, ZTZG’s round-to-square Rollers sharing process holds great promise for the future.

Post time: Dec-11-2024