The operating principles vary based on the type of steel pipe machinery:

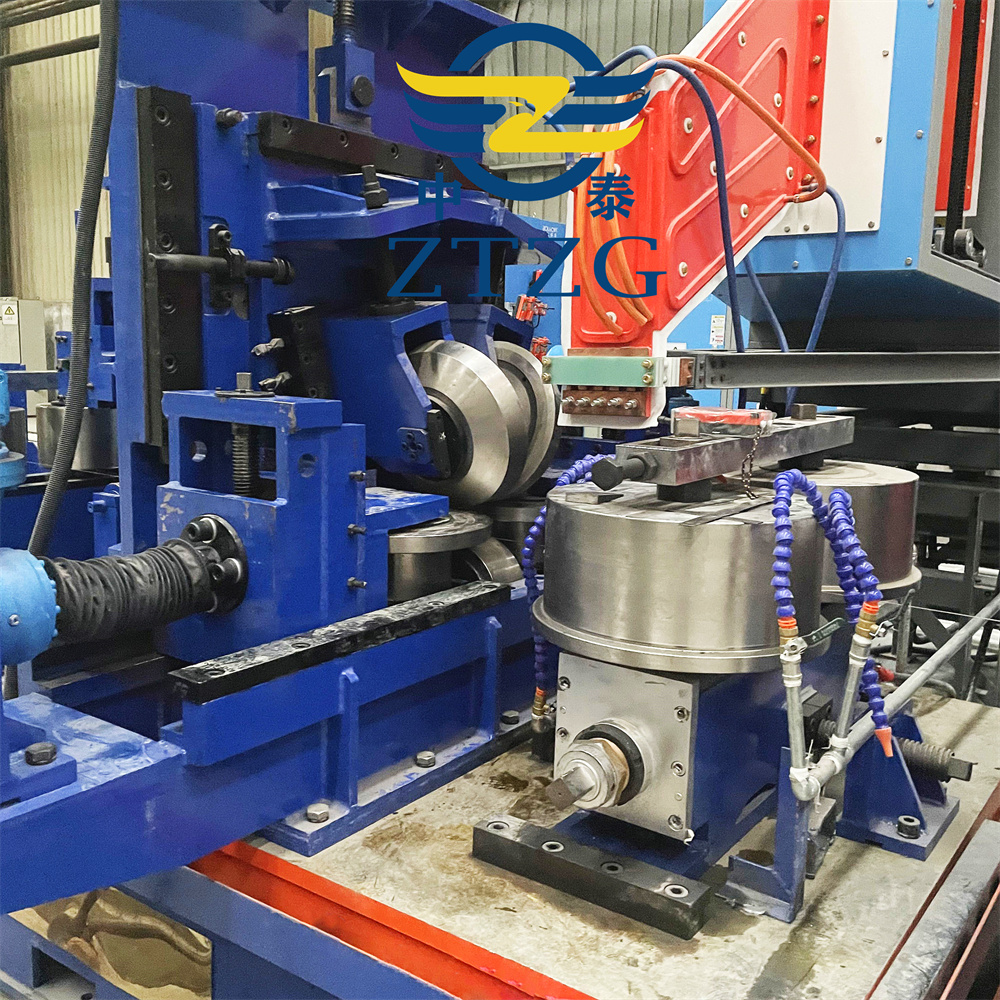

- **ERW Pipe Mills**: Operate by passing steel strips through a series of rollers that shape them into cylindrical tubes. High-frequency electrical currents are then used to heat the edges of the strips, creating welds as the strips are pressed together. This method ensures efficient production of welded pipes suitable for diverse industrial applications.

- **Seamless Pipe Mills**: Begin with heating cylindrical steel billets to a high temperature, followed by piercing to form hollow shells. These shells undergo rolling and sizing processes to produce seamless pipes with uniform dimensions and properties. Seamless pipe production ensures high strength, reliability, and resistance to internal pressure, making them essential for critical applications.

- **HF Welding Pipe Mills**: Utilize high-frequency induction heating to heat steel strips along their edges. The heated edges are then pressed together under pressure to create seamless welds. HF welding provides efficient production capabilities with precise control over welding parameters, suitable for manufacturing pipes with consistent quality and performance.

- **Laser Welding Pipe Mills**: Employ focused laser beams to melt and fuse the edges of steel strips or tubes. This non-contact welding method offers advantages such as minimal heat-affected zones, precise control over weld geometry, and the ability to weld dissimilar materials. Laser-welded pipes meet stringent quality requirements and are favored for applications demanding high weld integrity and aesthetic appeal.

These steel pipe machinery types illustrate diverse manufacturing capabilities tailored to meet specific industry demands, ensuring optimal performance and quality in pipe production.

Post time: Jul-29-2024