Many peers and friends do not have a deep understanding of mold automation, and the main reasons may be as follows:

Lack of frontline work experience

1. Not familiar with the actual operation process

People who have not worked on the front line of tube mils find it difficult to intuitively understand the specific operational changes before and after mold automation. For example, in traditional mold production, workers need to manually perform multiple complex processes such as installing, adjusting, and disassembling parts, which is not only time-consuming and labor-intensive, but also prone to human errors. In automated mold production, these processes can be accurately and efficiently completed by robots or automated equipment, greatly improving production efficiency and product quality. But without witnessing these practical operations firsthand, it is difficult to deeply appreciate the enormous advantages brought by automation.

Lack of awareness of technical details and challenges in frontline work. For example, in the process of mold processing, high precision is required, and traditional manual operations are difficult to ensure that every product meets consistent precision standards. Automated erw pipe mill equipment can achieve higher precision and stability through precise programming and control. Only by actually working on the front line can one truly feel the importance of these technical challenges and automation solutions.

2. Unable to understand the changes in work intensity and pressure

In frontline work, workers often face high-intensity labor and significant work pressure. Mold production often requires long periods of standing, repetitive movements, and high levels of attention, which can easily lead to fatigue and work-related injuries. Automation can alleviate the physical burden on workers, reduce work intensity and pressure, and improve work safety and comfort. People who have not experienced frontline work find it difficult to understand the actual benefits that this change brings to workers.

The intense pace and strict production requirements of frontline work can only be felt through personal experience. For example, in order to meet customer order demands, frontline workers may need to work overtime, and automation can improve production speed, shorten production cycles, and alleviate this tense production pressure. People who have not worked on the front line may not be able to appreciate the important role of automation in this regard.

Limited understanding of automation technology

Not familiar with automation equipment and systems

Many people lack understanding of the advanced equipment and systems involved in mold automation. For example, automated operations, robotic arms, automated temperature detection equipment, etc., the working principles, functions, and advantages of these devices may be unfamiliar to people who have not had contact with them. Without understanding the performance and characteristics of these devices, it is difficult to comprehend how they can improve the efficiency, accuracy, and quality of mold production.

The integration and control of automation systems is also a complex field. Knowledge in sensor technology, control systems, programming, and other related areas. People without relevant professional knowledge and frontline work experience find it difficult to understand how these systems work together to achieve automated processes in mold production.

Not sure about the benefits and value brought by automation

Lack of understanding of the economic, quality, and social benefits brought by mold automation. From the perspective of economic benefits, automation can reduce production costs, improve production efficiency, and increase the competitiveness of enterprises. For example, by reducing labor costs, improving equipment utilization, and reducing waste rates, significant economic benefits can be brought to enterprises. But without understanding these specific benefit indicators, it is difficult to feel the actual value of automation.

Quality and efficiency are also important advantages of mold automation. Automation can ensure product consistency and stability, improve product quality, reduce quality issues and customer complaints. However, for those who have not worked on the front line, it may be difficult to understand the importance of quality and efficiency for businesses.

In terms of social benefits, mold automation can reduce reliance on manual labor, improve production safety and environmental friendliness. But these social benefits often need to be understood from a more macro perspective, and people who have not worked on the front line may not easily pay attention to these aspects.

Insufficient information dissemination and education

Lack of relevant publicity and promotion

Mold automation, as an advanced production technology, needs to be effectively promoted and publicized to make more people aware of its advantages and value. However, currently in society, the promotion of mold automation is not strong enough, and many people have not had the opportunity to access relevant information. This has led to a lack of understanding and awareness of mold automation, making it difficult for them to form a profound feeling.

Enterprises may also have shortcomings when promoting mold automation. Some companies may focus more on their own economic benefits and neglect the promotion and education of the general public. This limits the public’s understanding of mold automation to only superficial concepts, without delving into its practical applications and value.

Insufficient emphasis on automation technology in the education system

In school education, there are relatively few courses and majors related to mold automation. This leads to a lack of systematic understanding and recognition of mold automation among students during the learning stage. Even if there are some related courses, due to limitations in teaching content and methods, students may not truly experience the practical application and importance of mold automation.

There is also a lack of targeted training on mold automation in terms of on-the-job training and continuing education. Many companies focus more on traditional skills and knowledge training in employee training, while neglecting the updating and improvement of automation technology. This makes it difficult for employees to access the latest automation technology in their work and form a deep understanding of mold automation.

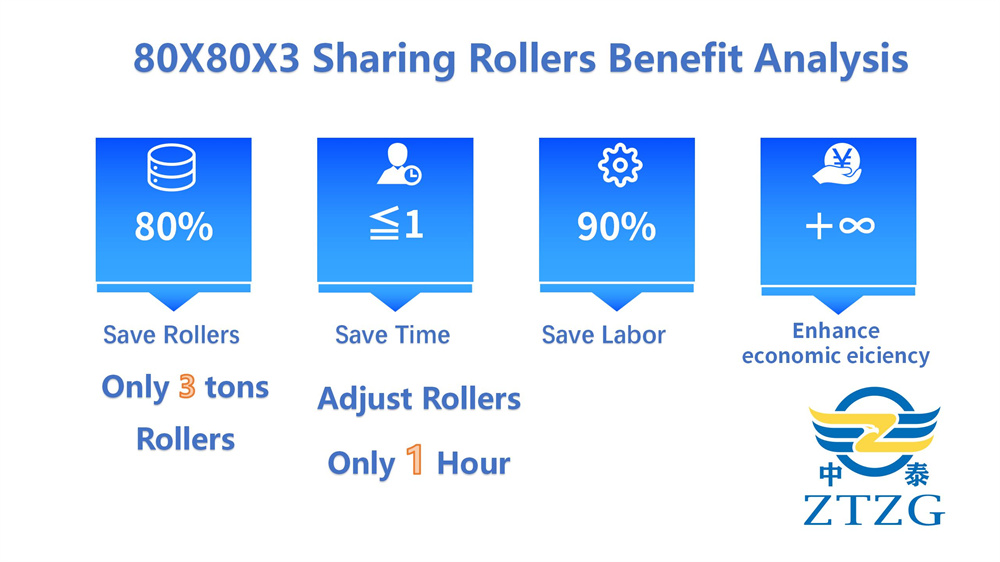

In the future, automation and upgraded AI technology will help workers work more safely and efficiently. The mold sharing pipe making machine mechanical equipment independently developed by ZTZG, equipped with an automated control system that has obtained relevant certifications, will provide workers with a safer and more comfortable working environment, and help upgrade China’s manufacturing to China’s intelligent manufacturing. In the midst of an economic downturn, we are striving to revitalize our national industry, making it our duty as both China and Thailand.

Post time: Dec-07-2024