OEM/ODM Supplier Rubber Calender Mill Machine Lab Rubber Textile Calender

Our advancement depends on the superior gear ,superb talents and consistently strengthened technology forces for OEM/ODM Supplier Rubber Calender Mill Machine Lab Rubber Textile Calender, Our enterprise warmly welcome close friends from everywhere in the environment to go to, examine and negotiate organization.

Our advancement depends on the superior gear ,superb talents and consistently strengthened technology forces for China Lab Rubber Calender and Rubber Calender Mill Machine, In order to carry out our goal of “customer first and mutual benefit” in the cooperation, we establish a expert engineering team and a sales team to supply the best service to satisfy our customers’ requirements. Welcome you to cooperate with us and join us. We are your best choice.

Description

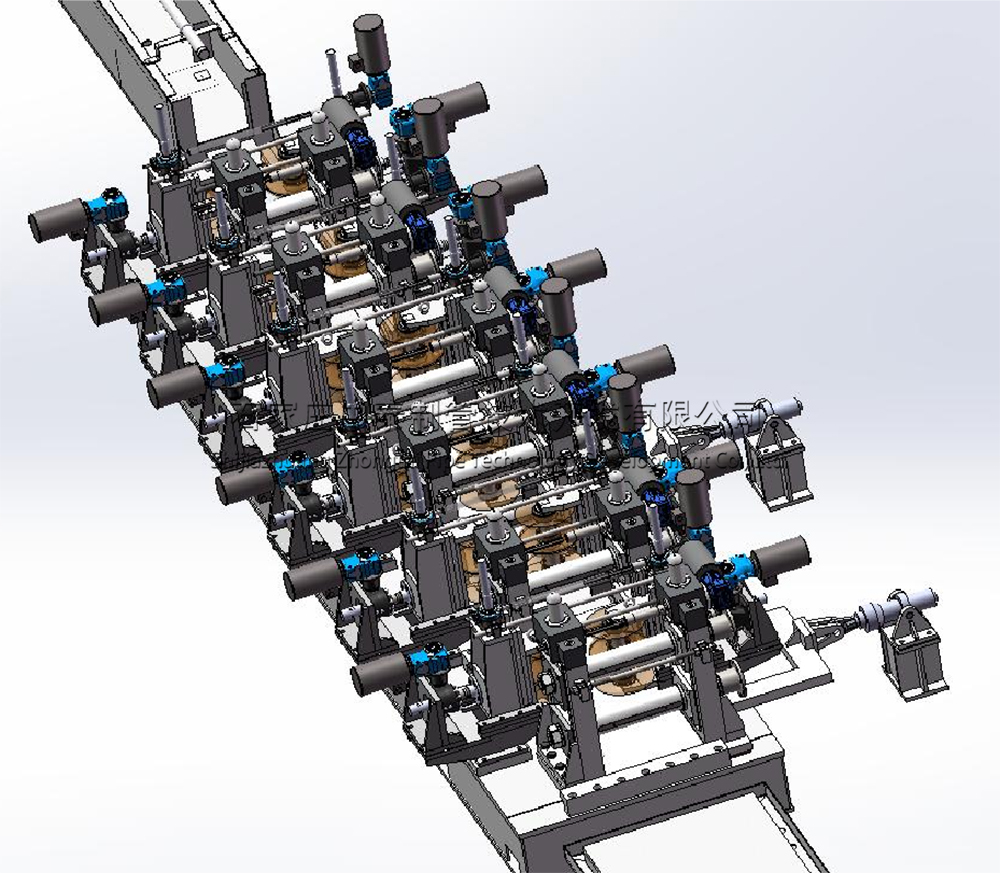

Multi-roller Quick-changing ERW Tubo Preduction Line is suitable when a production line has 2-3 specifications. There is no need to replace the mold, just place the corresponding mold on the roll shaft in advance, and the motor automatically adjusts the roll position without disassembly. When the diameter of the produced pipe is less than 50mm, three sets of molds can be placed.

1.Forming Section Share-roller:

1) Sizing Section Roller Quick-switching.

2) Load rollers for difference specifications and switch to the correct one when in forming.

3) Overturn traditional roller switch method .

4) High precision and higher automation level.

5) Suitable for smaller sized production lines that require frequent roller changes.

2.Round Pipe Full Line Share-roller:

1) set of roller to fullfill all specifications

2) Round pipe sizing section intellectual control and adjustment

3) Reduce the interference of human operation factors. Improve accuracy to achieve standardization

4) Cloud data service

Product information

| Product & Yield | Round Pipe | 10mm-89mm |

| Square & Rectangle Tube | 10x10mm-70x70mm | |

| Length | 6-12 m | |

| Production Speed | 50-120 m/min | |

| Production Capacity | 15000 ton | |

| Consumption | Mill Installed Capacity | 300-750 kw |

| Line Area | 40×5m-80×10m | |

| Worker | 6-8 workers | |

| Raw Material | Material | ST-37 ST-52 X42 X48 X52 X60 X70 |

| Width | 120mm-280mm | |

| Coil ID | Φ470~508mm | |

| Coil OD | Φ1000~1800mm | |

| Coil Weight | 2-5 ton |

Our Advantage

1. Reduce the labor intensity, reduce labor time of workers

2. Increase the output of pipes and improve production efficiency

3. No need to replace the mold,the production process is safer

4. Save roller change time

ZTZG’s long history and professional R&D capability in tube mill industry, it is known for its excellent product quality. we can design and manufacture pipe making machine according to customers’ requirements, and provide regular technical information and technical training support.

Our advancement depends on the superior gear ,superb talents and consistently strengthened technology forces for OEM/ODM Supplier Rubber Calender Mill Machine Lab Rubber Textile Calender, Our enterprise warmly welcome close friends from everywhere in the environment to go to, examine and negotiate organization.

OEM/ODM Supplier China Lab Rubber Calender and Rubber Calender Mill Machine, In order to carry out our goal of “customer first and mutual benefit” in the cooperation, we establish a expert engineering team and a sales team to supply the best service to satisfy our customers’ requirements. Welcome you to cooperate with us and join us. We are your best choice.

|

ERW TUBE MILL LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working spead m/min |

|

|

ERW20 |

Ф8-Ф20 |

6x6-15×15 |

0.3-1.5 |

120 |

Read More |

|

ERW32 |

Ф10-Ф32 |

10×10-25×25 |

0.5-2.0 |

120 |

|

|

ERW50 |

Ф20-Ф50 |

15×15-40×40 |

0.8-3.0 |

120 |

|

|

ERW76 |

Ф32-Ф76 |

25×25-60×60 |

1.2-4.0 |

120 |

|

|

ERW89 |

Ф42-Ф89 |

35×35-70×70 |

1.5-4.5 |

110 |

|

|

ERW114 |

Ф48-Ф114 |

40×40-90×90 |

1.5-4.5 |

65 |

|

|

ERW140 |

Ф60-Ф140 |

50×50-110×110 |

2.0-5.0 |

60 |

|

|

ERW165 |

Ф76-Ф165 |

60×60-130×130 |

2.0-6.0 |

50 |

|

|

ERW219 |

Ф89-Ф219 |

70×70-170×170 |

2.0-8.0 |

50 |

|

|

ERW273 |

Ф114-Ф273 |

90×90-210×210 |

3.0-10.0 |

45 |

|

|

ERW325 |

Ф140-Ф325 |

110×110-250×250 |

4.0-12.7 |

40 |

|

|

ERW377 |

Ф165-Ф377 |

130×130-280×280 |

4.0-14.0 |

35 |

|

|

ERW406 |

Ф219-Ф406 |

170×170-330×330 |

6.0-16.0 |

30 |

|

|

ERW508 |

Ф273-Ф508 |

210×210-400×400 |

6.0-18.0 |

25 |

Read More |

|

ERW660 |

Ф325-Ф660 |

250×250-500×500 |

6.0-20.0 |

20 |

Read More |

|

ERW720 |

Ф355-Ф720 |

300×300-600×600 |

6.0-22.0 |

20 |

Read More |

|

STAINLESS STEEL PIPE PRODUCTION LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working speed m/min |

|

|

SS25 |

Ф6-Ф25 |

5×5-20×20 |

0.2-0.8 |

10 |

Read More |

|

SS32 |

Ф6-Ф32 |

5×5-25×25 |

0.2-1.0 |

10 |

Read More |

|

SS51 |

Ф9-Ф51 |

7×7-40×40 |

0.2-1.5 |

10 |

Read More |

|

SS64 |

Ф12-Ф64 |

10×10-50×50 |

0.3-2.0 |

10 |

Read More |

|

SS76 |

Ф25-Ф76 |

20×20-60×60 |

0.3-2.0 |

10 |

Read More |

|

SS114 |

Ф38-Ф114 |

30×30-90×90 |

0.4-2.5 |

10 |

Read More |

|

SS168 |

Ф76-Ф168 |

60×60-130×130 |

1.0-3.5 |

10 |

Read More |

|

SS219 |

Ф114-Ф219 |

90×90-170×170 |

1.0-4.0 |

10 |

Read More |

|

SS325 |

Ф219-Ф325 |

170×170-250×250 |

2.0-8.0 |

3 |

Read More |

|

SS426 |

Ф219-Ф426 |

170×170-330×330 |

3.0-10.0 |

3 |

Read More |

|

SS508 |

Ф273-Ф508 |

210×210-400×400 |

4.0-12.0 |

3 |

Read More |

|

SS862 |

Ф508-Ф862 |

400×400-600×600 |

6.0-16.0 |

2 |

Read More |