Steel Pipe Production Line-Round to Square sharing rollers-ZTZG

Specialized in Pipe Production Line

More than 23 years...

Stainless Steel Pipe Production Line is designed to produce welded stainless steel pipes of 6mm to 862mm in OD and with a maximum wall thickness of 16mm, as well as corresponding square and rectangular pipe.

Steel Pipe Production Line

ZTZG Series Steel Welded Pipe Production Lines: Efficient and Reliable Tube Forming Solutions

The ZTZG series steel welded pipe production lines (tube mill / tube making machine) are specifically designed for the production of thick-walled carbon steel pipes (round pipes) primarily used in industrial sectors and high-requirement applications in decorative fields. This series of units can produce a variety of pipe profiles, including:

- Round Pipe: Meeting diverse industrial application needs.

- Square Pipe: Widely used in building structures and machinery manufacturing.

- Rectangular Pipe: Suitable for frame structures and decorative purposes.

- Special-Shaped Pipe: Including oval pipe, half-round pipe, plum pipe, and other customized profiles to meet specific requirements.

Key Advantages:

- High Precision Tube Forming: The ZTZG series tube making machine utilizes advanced roll sharing technology, ensuring precise pipe dimensions and excellent surface quality.

- High Efficiency Production: Optimized process flow and automated control systems significantly increase production efficiency and reduce production costs.

- Wide Range of Applications: Products are widely used in various industries, including oil, chemical, construction, machinery, automotive, and decoration.

- Customized Solutions: We can provide customized tube mill design and manufacturing solutions to meet specific customer needs.

Scrolling Up→ Uncoiling →Leveling machine →Shear welder → Horizontal spiral loop → Forming → Welding → Sizing→ Straightening→ Cutting → Run out table →Inspecting→ Packing→ Warehouse

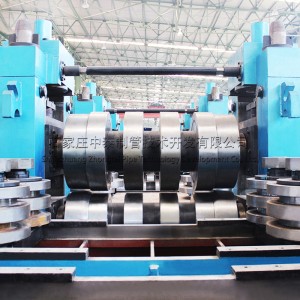

The Sharing Rollers Steel Pipe Production Line

"In addition, we have developed a new process for steel pipes with round and square diameter and wall thickness. This steel production line can realize the mold sharing of the entire production line

High Automation

One key adjustment of servo motor.

Low Wastage

Low unit wastage and low production cost.

High Accuracy

Diameter error is only 0.5/100 of the pipe OD.

Tube Making Machine Product Application

We can design and manufacture pipe making machine according to customers’ requirements.

Everything you need to create a steel pipe production line

Our Certificate

Our Company

Shijiazhuang Zhongtai Pipe Technology Development Co., Ltd.was established in 2000 locating in Shijiazhuang, the capital city of Hebei Province. The factory covers an area of 67,000 square meters. Our main products consist high frequency straight welded pipe production line, cold roll steel production line, multi-function cold roll steel/welded pipe production line, slitting line production line, stainless steel pipe mill, various pipe mill auxiliary equipment and rollers, etc.

Ready for a new

Business Adventure?

Contact Now!

|

ERW TUBE MILL LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working spead m/min |

|

|

ERW20 |

Ф8-Ф20 |

6x6-15×15 |

0.3-1.5 |

120 |

Read More |

|

ERW32 |

Ф10-Ф32 |

10×10-25×25 |

0.5-2.0 |

120 |

|

|

ERW50 |

Ф20-Ф50 |

15×15-40×40 |

0.8-3.0 |

120 |

|

|

ERW76 |

Ф32-Ф76 |

25×25-60×60 |

1.2-4.0 |

120 |

|

|

ERW89 |

Ф42-Ф89 |

35×35-70×70 |

1.5-4.5 |

110 |

|

|

ERW114 |

Ф48-Ф114 |

40×40-90×90 |

1.5-4.5 |

65 |

|

|

ERW140 |

Ф60-Ф140 |

50×50-110×110 |

2.0-5.0 |

60 |

|

|

ERW165 |

Ф76-Ф165 |

60×60-130×130 |

2.0-6.0 |

50 |

|

|

ERW219 |

Ф89-Ф219 |

70×70-170×170 |

2.0-8.0 |

50 |

|

|

ERW273 |

Ф114-Ф273 |

90×90-210×210 |

3.0-10.0 |

45 |

|

|

ERW325 |

Ф140-Ф325 |

110×110-250×250 |

4.0-12.7 |

40 |

|

|

ERW377 |

Ф165-Ф377 |

130×130-280×280 |

4.0-14.0 |

35 |

|

|

ERW406 |

Ф219-Ф406 |

170×170-330×330 |

6.0-16.0 |

30 |

|

|

ERW508 |

Ф273-Ф508 |

210×210-400×400 |

6.0-18.0 |

25 |

Read More |

|

ERW660 |

Ф325-Ф660 |

250×250-500×500 |

6.0-20.0 |

20 |

Read More |

|

ERW720 |

Ф355-Ф720 |

300×300-600×600 |

6.0-22.0 |

20 |

Read More |

|

STAINLESS STEEL PIPE PRODUCTION LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working speed m/min |

|

|

SS25 |

Ф6-Ф25 |

5×5-20×20 |

0.2-0.8 |

10 |

Read More |

|

SS32 |

Ф6-Ф32 |

5×5-25×25 |

0.2-1.0 |

10 |

Read More |

|

SS51 |

Ф9-Ф51 |

7×7-40×40 |

0.2-1.5 |

10 |

Read More |

|

SS64 |

Ф12-Ф64 |

10×10-50×50 |

0.3-2.0 |

10 |

Read More |

|

SS76 |

Ф25-Ф76 |

20×20-60×60 |

0.3-2.0 |

10 |

Read More |

|

SS114 |

Ф38-Ф114 |

30×30-90×90 |

0.4-2.5 |

10 |

Read More |

|

SS168 |

Ф76-Ф168 |

60×60-130×130 |

1.0-3.5 |

10 |

Read More |

|

SS219 |

Ф114-Ф219 |

90×90-170×170 |

1.0-4.0 |

10 |

Read More |

|

SS325 |

Ф219-Ф325 |

170×170-250×250 |

2.0-8.0 |

3 |

Read More |

|

SS426 |

Ф219-Ф426 |

170×170-330×330 |

3.0-10.0 |

3 |

Read More |

|

SS508 |

Ф273-Ф508 |

210×210-400×400 |

4.0-12.0 |

3 |

Read More |

|

SS862 |

Ф508-Ф862 |

400×400-600×600 |

6.0-16.0 |

2 |

Read More |