Supply ODM Steel Tube Straightening Machine

With our outstanding management, robust technical capability and strict top quality regulate system, we carry on to supply our shoppers with reputable top quality, reasonable charges and excellent companies. We purpose at becoming amongst your most reliable partners and earning your fulfillment for Supply ODM Stainless Steel Tube Straightening Machine, Clients to start with! Whatever you require, we should do our utmost to aid you. We warmly welcome prospects from everywhere in the entire world to cooperate with us for mutual enhancement.

With our outstanding management, robust technical capability and strict top quality regulate system, we carry on to supply our shoppers with reputable top quality, reasonable charges and excellent companies. We purpose at becoming amongst your most reliable partners and earning your fulfillment for China Pipe Straightening Machine and Pipe Straightener, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

Description

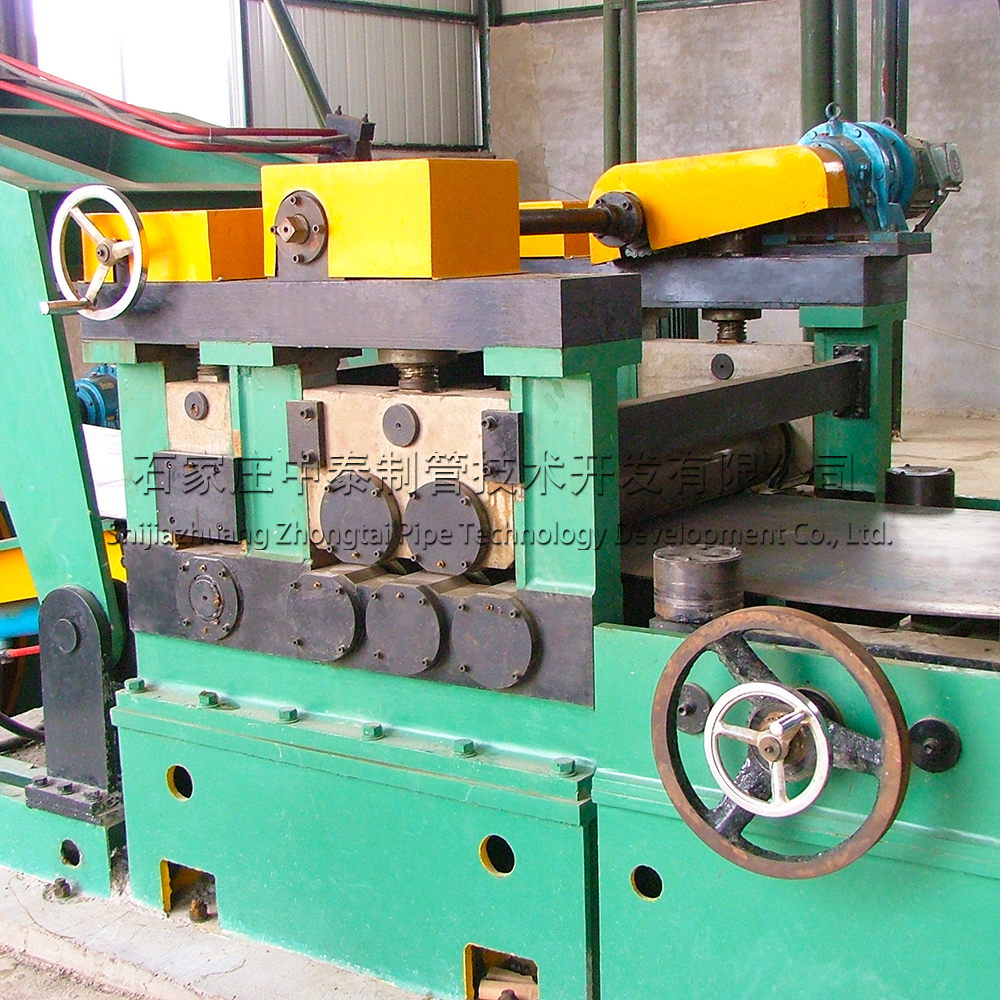

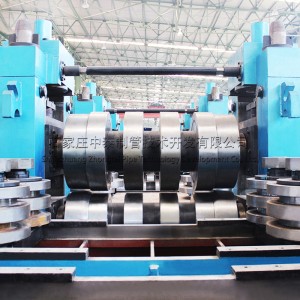

This machine operation is convenient and accurate. On the console, the inlet and outlet reduction can be set according to the parameters such as plate thickness, plate width, material and original curvature. The display accuracy is ± 0.1mm, and automatic control is realized. PLC has the function of editing, storing and memorizing process parameters. When in use, it can be called and corrected at any time, which is very convenient to operate.

roller pitch and the number of work rolls. The work rolls can also be backed up for more precise flatness and zone control. Essentially, the closer the roller pitch and the smaller the leveling roller diameter, the better the result depending on the thickness and yield of the material. A leveler is superior to a straightener as the leveler will remove more than cross bow or coil set.

1. Leveling machine is the important parts . It will influence the flatness of the final sheets.

2. It is designed with 11 pieces leveling roller and 2 groups of back-up roller design to ensure the leveling quality

3. The upper rollers can be lift up and down by motor as per different thickness

ZTZG is strict quality control in raw materials, processing accuracy, heat treatment, assembly accuracy, standard parts, etc. The pass rate of equipment delivery is 100%.

Product Information

| Applicable Industries | Building Material Shops, Construction works , Energy & Mining |

| Voltage | 380v/50hz/3ph |

| Power | 55kw |

| Dimension(L*W*H) | 4x3x2.5 |

| Weight | 10T |

| Length precision | ±1.5mm |

| Certification | ISO9001 |

| Control model PLC control | PLC control |

| After Warranty Service | Video technical support, Online support, Spare parts, Field maintenance and repair service |

| After-sales Service Provided | Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support, Engineers available to service machinery overseas` |

With our outstanding management, robust technical capability and strict top quality regulate system, we carry on to supply our shoppers with reputable top quality, reasonable charges and excellent companies. We purpose at becoming amongst your most reliable partners and earning your fulfillment for Supply ODM Stainless Steel Tube Straightening Machine, Clients to start with! Whatever you require, we should do our utmost to aid you. We warmly welcome prospects from everywhere in the entire world to cooperate with us for mutual enhancement.

Supply ODM China Pipe Straightening Machine and Pipe Straightener, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

|

ERW TUBE MILL LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working spead m/min |

|

|

ERW20 |

Ф8-Ф20 |

6x6-15×15 |

0.3-1.5 |

120 |

Read More |

|

ERW32 |

Ф10-Ф32 |

10×10-25×25 |

0.5-2.0 |

120 |

|

|

ERW50 |

Ф20-Ф50 |

15×15-40×40 |

0.8-3.0 |

120 |

|

|

ERW76 |

Ф32-Ф76 |

25×25-60×60 |

1.2-4.0 |

120 |

|

|

ERW89 |

Ф42-Ф89 |

35×35-70×70 |

1.5-4.5 |

110 |

|

|

ERW114 |

Ф48-Ф114 |

40×40-90×90 |

1.5-4.5 |

65 |

|

|

ERW140 |

Ф60-Ф140 |

50×50-110×110 |

2.0-5.0 |

60 |

|

|

ERW165 |

Ф76-Ф165 |

60×60-130×130 |

2.0-6.0 |

50 |

|

|

ERW219 |

Ф89-Ф219 |

70×70-170×170 |

2.0-8.0 |

50 |

|

|

ERW273 |

Ф114-Ф273 |

90×90-210×210 |

3.0-10.0 |

45 |

|

|

ERW325 |

Ф140-Ф325 |

110×110-250×250 |

4.0-12.7 |

40 |

|

|

ERW377 |

Ф165-Ф377 |

130×130-280×280 |

4.0-14.0 |

35 |

|

|

ERW406 |

Ф219-Ф406 |

170×170-330×330 |

6.0-16.0 |

30 |

|

|

ERW508 |

Ф273-Ф508 |

210×210-400×400 |

6.0-18.0 |

25 |

Read More |

|

ERW660 |

Ф325-Ф660 |

250×250-500×500 |

6.0-20.0 |

20 |

Read More |

|

ERW720 |

Ф355-Ф720 |

300×300-600×600 |

6.0-22.0 |

20 |

Read More |

|

STAINLESS STEEL PIPE PRODUCTION LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working speed m/min |

|

|

SS25 |

Ф6-Ф25 |

5×5-20×20 |

0.2-0.8 |

10 |

Read More |

|

SS32 |

Ф6-Ф32 |

5×5-25×25 |

0.2-1.0 |

10 |

Read More |

|

SS51 |

Ф9-Ф51 |

7×7-40×40 |

0.2-1.5 |

10 |

Read More |

|

SS64 |

Ф12-Ф64 |

10×10-50×50 |

0.3-2.0 |

10 |

Read More |

|

SS76 |

Ф25-Ф76 |

20×20-60×60 |

0.3-2.0 |

10 |

Read More |

|

SS114 |

Ф38-Ф114 |

30×30-90×90 |

0.4-2.5 |

10 |

Read More |

|

SS168 |

Ф76-Ф168 |

60×60-130×130 |

1.0-3.5 |

10 |

Read More |

|

SS219 |

Ф114-Ф219 |

90×90-170×170 |

1.0-4.0 |

10 |

Read More |

|

SS325 |

Ф219-Ф325 |

170×170-250×250 |

2.0-8.0 |

3 |

Read More |

|

SS426 |

Ф219-Ф426 |

170×170-330×330 |

3.0-10.0 |

3 |

Read More |

|

SS508 |

Ф273-Ф508 |

210×210-400×400 |

4.0-12.0 |

3 |

Read More |

|

SS862 |

Ф508-Ф862 |

400×400-600×600 |

6.0-16.0 |

2 |

Read More |